It’s more than just power, it’s teaching potential: Vernier Go Direct Sensors and Micro USB Charging

By Martin Horejsi

Posted on 2017-04-14

Power powers. It’s that simple. With all our digital tools, there is at least one common thread across it all and that is we need a flow of electrons to keep the teaching and learning in high gear. But of course batteries die. There are four common battery solutions in our digital devices. One is onboard and built-in rechargeable lithium-ion battery packs. Another is a removable lithium-ion battery pack. A third is common grocery store batteries like AA, AAA, and CR2032, among others. And a forth option is some combination and interchangeability of the above. Of course there are hard-wired connection to AC outlets, but those are so limiting that we only use them only for larger devices, static lab-based tools, and those instrument firmly bolted to a desk or other base station.

Ahh, but once in the rechargeable realm, a new set of issues can arise. The major factor being the connector required to attach the device to a power source. Way back in the early 2000s and of course earlier, there were many options for connectors. From pin-sized small round connectors, larger round connectors, square connectors, to at least four USB connectors, to proprietary Apple connectors.

In 2009, it almost all changed when a European Commission initiative created a “Common External Power Supply” or EPS that was adopted by almost all major cell phone companies. Notably, Apple was the hold out continuing with their proprietary 30-pin connector, and more recently their Lightning connector.

Companies that made other devices slowly adopted the industry standard using the Micro USB port standard for power and recharging. A slightly larger connector, the Mini USB port, was a common go-to connectors, but had little advantage over the micro USB except for port orientation directionality (it was easier to tell which way to orient the cable), and a slightly overall connector strength when under cable stress.

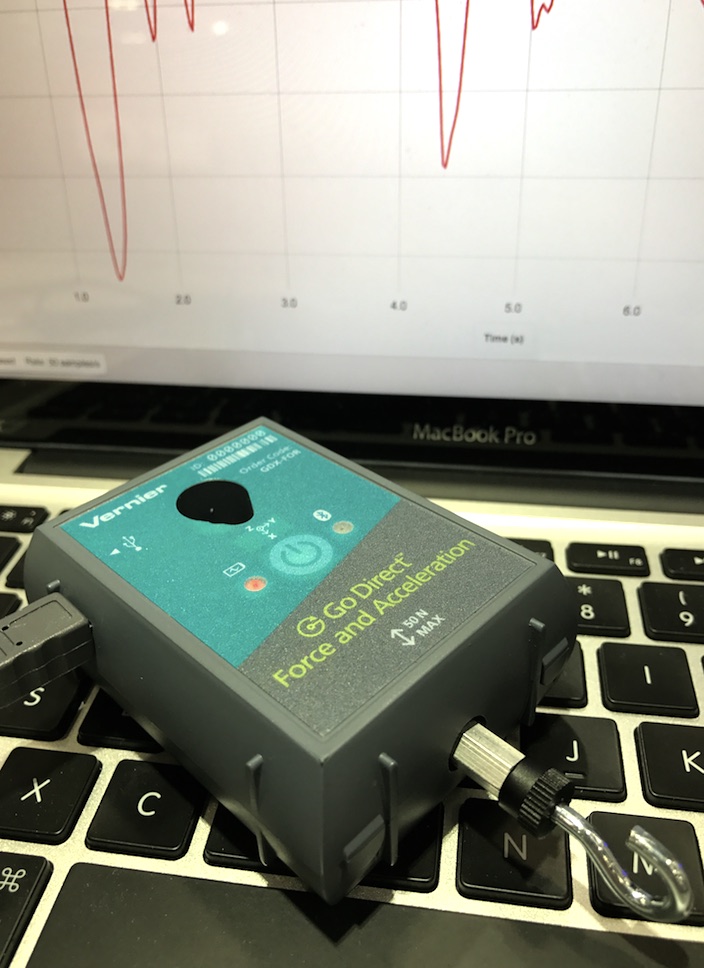

Vernier Technologies, creator of some the most innovative and useful digital sensors, probes, and software used its own proprietary connector design for it’s Go Wireless line of sensors. But this year, it has added the Common External Power Supply connector to its sensors that contain internal lithium-ion batteries and other upgrades calling the new sensor line Go Direct. The micro USB port provides three distinct advantages over anything proprietary. First, it is a common connector in both the sense that many devices use it, and common there are many options for power supplies when using the micro USB.

In the past, many of use had bins, boxes, drawers, or bags filled with various charging cables all hardwired to specific connectors. I remember once vowing to myself that I would never buy a certain brand’s product because the required cable was not only proprietary but also seemingly excessively expensive for a simple cable. It was maddening to pay upwards of $40 for a small cable that only worked with one specific device. When I did the mental math, the cable cost about one-fifth of the entire device. How could that be?

Even today, I am not free of cableage. In my go-bag for conference presentations, I carry cables for USB-A, B, and now C, Ethernet, VGA, HDMI, 30-pin Apple, Lightning, Firewire, and 3.5mm audio, and a Class C C7 power connector. And soon missing from my cable carry will be the Vernier cradle for its Go sensors.

Labs just got simpler. Vernier Technologies has added the micro UBS port to its Go Sensors. So now the new version of it’s sensors can recharge using both the traditional Vernier Go sensor charging cable and dock, as well as a universal micro USB port. This is a welcome addition since on more than one occasion I have been out in the field in need of a charge but without a handy Vernier proprietary charging cradle. Further, like smartphones, the data collection can continue with an external battery attached leading to the potential of literally unlimited data collection times due to the limitless and unlimited supply of electrons that can be piped into the sensor’s on-board lithium ion battery. Whether solar, hydro, or coal-fired, the electrons can flow. They can even flow from plenty of portable solutions that recharge our devices including my favorites that draw electrons from my high capacity power tool batteries including the Milwaukee Tools 12 volt and 18 volt FUEL battery options.

Replaceable batteries have some advantages in that they can be replaced when needed, but they do require an interruption in activity while the batteries are swapped. A second problem is that a battery discharges with use so often we head into the next class or teaching day with used batteries. We might have a pocketful of new batteries, but swapping out batteries with some charge left is not easy for a teacher on a limited budget. So enter the on-board rechargeable.

When a rechargeable is built into the device and recharged on the fly especially when in use, the advantage is tremendous. Every science class can have fresh full batteries, and if the data collection pushes up against the capacity of the battery, it can be charged while in use without data collection interruption. And this goes for cell phones, cameras, sensors, and lights.

So until we have onboard power generation from solar cells or mini-nuclear plants, we will have to be happy with common-connector recharging of onboard power with our science teaching tools. And a more powerful cable than the standard DC two-lead cable provides a chance to connect to a computer and stream data independent of a wireless connection. Vernier’s new line of Go Direct sensors are yet another step in the right direction of unlimited teaching potential. Stay tuned for more on the individual sensors and probes.

Disclaimer: The views expressed in this blog post are those of the author(s) and do not necessarily reflect the official position of the National Science Teaching Association (NSTA).