Safety Blog

Gearing Up Instructional Spaces Safety-Wise for the New School Year, Part II

By Ken Roy

Posted on 2023-08-28

Disclaimer: The views expressed in this blog post are those of the author(s) and do not necessarily reflect the official position of the National Science Teaching Association (NSTA).

In last month’s blog post, we discussed preparing for the new school year (see https://www.nsta.org/blog/gearing-instructional-spaces-safety-wise-new-school-year-part-i), highlighting the assessments that must take place and four of the Standard Operating Procedures (SOPs) that must be put in place to ensure a safer science/STEM environment. In this month’s blog post, we will continue the discussion about SOPs and summarize the discussion.

II. Need for SOPs (continued)

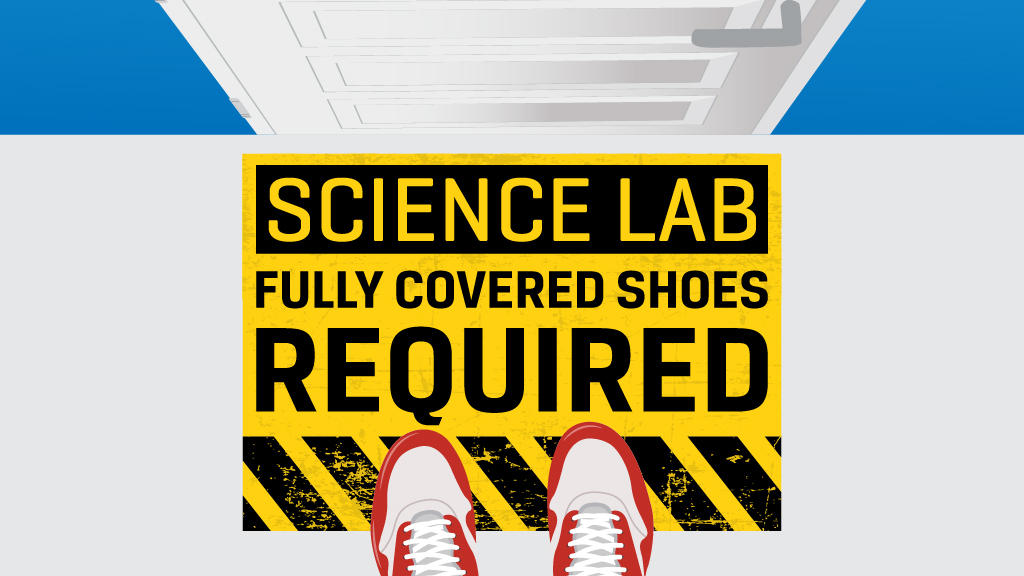

E. Apparel. While working in the instructional spaces involving biological, chemical, or physics hazards, bare feet and open-toed or perforated shoes are not permitted. Also, oversized sleeves, dangling jewelry, etc., should not be worn, as they may interfere with the preparation/handling of materials. Cover bare skin with long sleeves or a laboratory coat appropriate for the biologicals or chemicals used. If a student is not dressed appropriately for an activity, do not allow them to conduct the activity and have them leave the instructional site.

F. Personal Protective Equipment (PPE). Indirectly vented chemical splash goggles meeting the ANSI/ISEA Z87.1 D3 standard (https://resources.duralabel.com/articles/ansi-z871-eye-safety-eye-protection-glasses#:~:text=Eyewear%20that%20meets%20ANSI%20Z87,splashes%20is%20marked%20with%20%E2%80%9CD3%E2%80%9D) shall be worn when handling hazardous chemical or biological liquids that have the potential to splash the eyes. Goggles or safety glasses with side shields can be used when working with physical hazards (e.g., power tools, hand tools, springs, glassware, etc.). Gloves and aprons or a laboratory coat appropriate for the material shall be worn when using chemicals, biologicals, heated items, certain tools, etc. For specific hazardous chemical PPE requirements, consult Safety Data Sheet (SDS) Section VIII for appropriate PPE use. Face shields along with safety goggles—never in place of safety goggles—shall be worn when preparing and/or transferring corrosive materials or where there is the possibility of chemical splash.

Each state has their own guidelines for goggle usage in the science/STEM instructional areas. Teachers must make sure that they are well-versed in these guidelines, that they use the appropriate goggles, that they enforce their proper usage in the classroom, and that all occupants wear them whenever appropriate safety actions require them to be worn.

Eye, face, hand/arm, head, and body protection (leather gloves, leather apron, gauntlets, safety glasses with side shields, welder’s helmet or welder’s goggles) are required PPE that are appropriate to the potential hazards encountered during welding, cutting, brazing, soldering, grinding, or other spark- producing operations. Again, be aware of and follow the local and state guidelines for wearing the appropriate PPE and enforce their usage by everyone in the instructional space.

When PPE is required for any activity, the teacher must show and have written documentation that they have shown the students the proper use of the PPE, including how to sanitize PPE, put it on, and take it off. Never assume students already learned how to do this. Also note that states have specific goggle statutes for students that must be adhered to: e.g., 2012 Connecticut General Statutes: Title 10, Education and Culture, Chapter 169—School Health and Sanitation, Section 10-214a—Eye-protective devices—https://law.justia.com/codes/connecticut/2012/title-10/chapter-169/section-10-214a/, and New Jersey Admin. Code § 6A:26-12.5, Eye Protection in Schools (https://casetext.com/regulation/new-jersey-administrative-code/title-6a-education/chapter-26-educational-facilities/subchapter-12-safety-requirements-for-school-facilities/section-6a26-125-eye-protection-in-schools).

G. Chemical Recycling. All chemicals to be recycled must be stored in a specifically designated area according to their SDSs. It is best to keep them in trays in case of leakage. Recycling containers shall be labeled as required under appropriate regulations. Every attempt will be made to remove chemicals to be recycled within one calendar year by a licensed pre-approved contractor. Consult your Chemical Hygiene Officer and/or local landfill or recycling plan supervisor for more information. A recycling plan should be put in place and considered before a chemical is purchased.

H. Engineering Controls. Instructional space engineering controls generally include the following: Appropriate ventilation, fume hood and/or spray booth, goggle sanitizer cabinet, fire extinguishers [ABC, D Types (as appropriate)], fire blanket, gas shutoff switch, eyewash station, drench type safety shower, ground-fault circuit interrupter (GFCI) outlet, local exhaust ventilation to capture and remove airborne emissions, machine guards to shield the worker, etc. For example, make sure all power tools have appropriate and functional machine guards in place before allowing students or other employees to use the machines. Preventative maintenance is critical in ensuring these engineering controls are operational and functioning at the required levels before any lab activities begin. Consult your SDS sheets and your manufacturer’s operating instructions for the appropriate and required engineering controls. If you do not have the appropriate engineering controls in working order, do not conduct the activity and do not use the equipment.

I. Plumbing Systems. To prevent the accumulation of chemical or biological hazards in the instructional space water sources, the following actions need to be taken:

- The plumbing systems need to be flushed once a week. This includes when school is not in session.

The possibility of biological hazards (e.g., bacteria, mold, etc.), chemical hazards (e.g., copper and lead, hydrogen sulfide, etc.) and physical hazards (e.g., particulate residue, etc.) building up in your pipes could lead to unsafe health hazards and serious consequences. The buildup of bacteria alone can cause Legionnaire’s disease in your pipes, which potentially can be inhaled into the human body. https://www.mayoclinic.org/diseases-conditions/legionnaires-disease/symptoms-causes/syc-20351747#:~:text=Legionnaires%27%20disease%20is%20a%20severe,bacteria%20from%20water%20or%20soil. (Read June 5, 2021) This buildup can potentially occur when there is standing water in your pipes.

- In instructional laboratory spaces, safety systems need to be activated every week. This includes eyewash stations and safety showers. Again, if these systems are not activated (flushed) weekly, water contaminants can build up in the pipes. Biological, chemical, and physical contaminants can potentially get trapped in the plumbing, making the water in these safety systems compromised and unsafe for use.

- Continue the weekly testing of the water systems.

- Log the safety tests.

- These flushing actions should also be taken during every summer.

- Get a copy of the summer testing logs to ensure the work was done in your absence.

- A written log of all safety tests, including the flushing of the plumbing system, must be maintained and accessible at all times. Any issues related to the plumbing system need to be communicated in writing. If the plumbing system is not working appropriately, do not use the instructional space for activities requiring the use of the systems; i.e., any activity requiring a safety shower or eyewash stations.

J. 3-D Printers SOPs. Investigate if the current air-filtration system for 3-D printers meets the appropriate federal, state, and/or locally mandated air-changes-per-hour (ACH) rate for the equipment being used and activities being performed. When operating the printers, ensure that gas and particle air-filtration systems (i.e., electrostatic air filter) in the instructional space are always turned on and functioning properly when 3-D printers are in operation. Operating 3-D printers in exhaust ventilation fume hoods or spray booths is a safer means of prudently avoiding exposure to potentially harmful Ultrafine Particles (UFPs) and Volatile Organic Compounds (VOCs). Use Polylactic Acid (PLA) instead of Acrylonitrile Butadiene Styrene (ABS) material for 3-D printing, since it has been found to emit safer UFP concentrations.

K. HVAC Operations. HVAC ventilation systems require suitable filters in place for appropriate air exchange. Assuming that the appropriate filters are in place, they must be inspected by a trained heating/ventilation technician and replaced regularly (four or more times a year is recommended) for optimal filtering and functioning of the system. Consult local and state guidelines and legal standards for additional information and guidance. Remember under National Fire Protection Association (NFPA) 45, HVAC units for instructional spaces, storage rooms, etc., involving hazardous (flammable, etc.) chemicals are to run ongoing and are not to be recycled elsewhere in the building. There should be an up-to-date and accessible log outlining the inspection dates and filter replacement schedule.

L. Housekeeping Requirements. Employees are expected to actively engage in prudent instructional space housekeeping practices. In addition to chemical and biological hazards, physical hazards such as trip/slip, fall, and electrical hazards are to be eliminated, and the spaces should be neat and orderly to prevent accidents.

M. First Aid. Examples of potential laboratory accidents include heat/chemical burns, penetrating objects, electrical burns, swallowed poisons, bleeding chemical exposure, lacerations, shock, skin cuts, and allergic reactions. The school nurse should provide professional development at the beginning of each school year on how the instructional space teachers can initially respond to these types of accidents until medical assistance arrives. Each educator must be trained on how to deliver the first aid they are expected to provide, whom to contact in case of an accident, and how to use the class phone to dial out in an emergency.

N. Instructional Space Signage. Appropriate signage must be posted in instructional spaces where potential biological, chemical, or physical hazards exist. Signage includes but is not limited to eye wash, emergency shower, fire extinguisher, spill kit, master electrical and gas shutoffs, and fire/evacuation escape routes. Also use NFPA 704 Warning Placards. The NFPA 704 Diamond, commonly referred to as the NFPA Hazard Diamond, provides a system for identifying the specific hazards of a material and the severity of the hazard that would occur during an emergency response. Any instructional space and/or support areas containing chemical hazards need to have the NFPA 704 Warning Placard on the door. Rooms should be inspected regularly to make sure that the appropriate signage is in place and has not been removed.

O. Safety Work Zone Requirements. Make sure there are safety work zones in the instructional space painted or marked around machinery on the floor. Remember that the largest piece of work being made on one machine cannot interfere with the largest piece of work being worked on at the same time on an adjacent machine. There should also be 28 inches of walking clearance between the machines when both parts are loaded. The floor must be marked in such a way as to prevent another person (other than the operator) from being able to reach the danger zone of the machine while it is in operation. See https://www.gov.nl.ca/education/files/k12_curriculum_documents_skilledtrades_safety_zones.pdf for additional recommendations about safety work zones for specific STEM lab machinery.

P. Accessibility for Special-Needs Students. Teachers need to remember that there is a difference between making accommodations for students and modifying an assignment/assessment for students. According to NSTA, “Accommodations are changes made to the lab environment to the available lab equipment, or in how the lab is being completed by a student. Modifying a lab would involve changing the content of the lab, and therefore modifying your expectations of what that student is required to complete.” For planning purposes, refer to some suggestions of accommodations and modifications frequently used to support students with special needs during lab activities in this article from NSTA's middle level journal, Science Scope: “Modifying Labs for Students With Special Needs” at https://www.nsta.org/science-scope/science-scope-january-2020/modifying-labs-students-special-needs.

III. Final Words

For a safer instructional space teaching/learning experience starting at the beginning of and continuing through the school year, safety assessment, preparation of SOPs, and continued enforcement of all safety protocols are key! To meet the expectation of a safer instructional environment, assessments must be carried out before the start of the school year, and standard operating safety procedures must be established and addressed from the first day teachers report for the new school academic year: e.g., inspection, correction, training, etc., and implemented before students begin the new school year. Have a safer school year!

Submit questions regarding safety to Ken Roy at safersci@gmail.com. Follow Ken Roy on Twitter: @drroysafersci.

Safety Blog Acknowledgement. NSTA Chief Safety Blogger Dr. Ken Roy wishes to sincerely thank nationally recognized District Supervisor of Science Kevin S. Doyle, Ed. D., Morris Hills Regional District, Rockaway, New Jersey (kdoyle@mhrd.org) for his professional review of and contributions to this commentary.

Safety Technical and Vocational Education Elementary Middle School High School Postsecondary Informal Education