Measuring Murphy’s Law with the Vernier Go Direct Acceleration Sensor

By Martin Horejsi

Posted on 2019-08-28

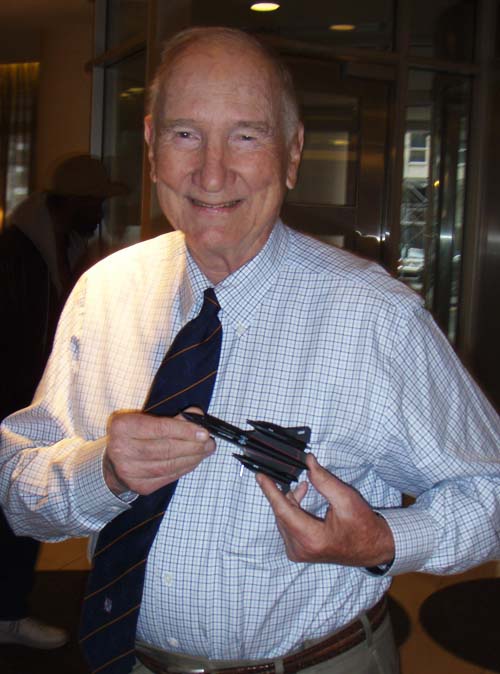

On the 4th of July this year, a fitting date, America lost a true hero whom many people had never heard of, namely Robert Gilliland. Bob Gilliland was the chief test pilot and first person to fly the iconic SR-71 Blackbird, arguably the coolest airplane in history.

Even without all its world records, the profile of the Blackbird has inspired and awed generations for generations. And if the first SR-71 flight wasn’t enough, Bob took the beautiful new Blackbird to supersonic speed on its maiden voyage back in December of 1964. Something unheard of! And Bob told me he flew the first flight of every Blackbird to follow ultimately logging more time at mach 2 and mach 3 that anyone else on earth.

In order to get up to those supersonic speeds in a reasonable amount of time, the Blackbird accelerates at around 20 meters per second or about 10 times faster than a commercial airliner taking off. The pilot of an SR-71 experiences the feeling of about 2 g, or twice the usual tug of the earth. That impressive force you feel when your Boeing 737 takes is only adding about two-tenths of a g.

Acceleration is a change in velocity where velocity is a change in position. While basic on the surface, acceleration causes much confusion in the science classroom. And speaking of confusion, the famous, infamous rather, Area 51 was where the SR-71 was born.

The Skunkworks in Area 51 was home to Clarence “Kelly” Johnson, the legendary aircraft designer. I read as story about Kelly where he was in a meeting to discuss a new military aircraft. Several requirements for the plane were given and Kelly, in his head, calculated the necessary wing surface area and shape to get the job done. Remember, powerful computers, CAD, and the internet were still a long ways off in the future. Which leads me to another story, one that Bob Gilliland told me personally. First, remember that Bob was flying around in the SR-71 at 85,000 feet at three times the speed of sound. The SR-71 could fly about 3000 miles on a tank of gas, or roughly 90 minutes. To do an extended international mission, a supporting team of aerial refueling tankers had to be staged along the route. So in the era prior to GPS navigation, there was Bob with map on knee dropping to about as low and slow as the Blackbird could fly to mate up with a fuel tanker in a sky dance with the tanker flying as fast as it can. Time was critical as the now-inefficient SR-71 engines were struggling in the dense air. I imagine it somewhat like a Star Trek or Star Wars scene where a ship traveling faster than light suddenly slows and just appears in a new place. Bob told me, and I quote, “You’ve never been lost until you’re lost at mach three!”

Mach 3 is 38 miles a minute, or over half a mile a second. A few minutes of miscalculation and you could be over the wrong state or even the wrong country!

Now once a vehicle is at it’s cruising speed whether bicycle of Blackbird, the sensation of movement maybe impossible. As anyone knows who has had a very smooth flight on an airliner, at cruising speed it’s impossible to tell with your eyes closed if the plane is sitting still on the ground, or flying at 500 miles per hour at 37,000 feet. Thus is the magic of acceleration. Only change is detectable.

Golf clubs, tennis rackets, and baseball bats are also obvious candidates for science fun. In fact, since all activities involve movement (hence the name activity), the Vernier Go Direct Acceleration sensor could be used to create science experiments almost anywhere. I can even imagine an entire science fair where the Vernier Go Direct Acceleration sensor was used in every single student’s scientific inspection of something. Hmm, maybe there is room for a Acceleration Fair?

Prior to the development of the SR-71, the parameters of the human body with regard to acceleration, or rather deceleration, were hot topics. How much deceleration could a human take and remain conscious, or even remain alive? To explore that physiological avenue, rocket sleds and centerfuges were used where “living sensors” were strapped into a seat and subjected to incredible speeds and slow-downs. One such engineer on the project was named Edward Murphy who proposed using strain gauges in addition to live subjects. It was the beginning of the popular use of Murphy’s Law when in one centrifuge trial every one of the strain gauges were wired backwards.

But I have another take on this. If there was no directional indication on the strain gauges, then there is a likelihood that at least one of the gauges would have been wired correctly. And statistics would support that half would be wired right. But since all sensors were backwards, something else seems to be at work. And that something else, in my mind, is a backwards understanding of how the acceleration would be measured by the strain gauges. Remember, the key measurement of interest was the slowing of the subject, not the speeding up. Or “eyeballs out” in fighter pilot vernacular.

Fast forward to September 8, 2004. On that day, an elegant spacecraft named Genesis was returning to earth after a three year mission collecting solar wind particles on hundreds of thin wafers each a hexagon about the size of a playing card. The fragile wafers were of 15 different materials including sapphire, gold, amorphous carbon, germanium, and silicon like the one I have in my teaching collection. It would be the first sample return mission to arrive back on earth since Apollo 16 back in 1972.

Because these wafers were so fragile, a complex and Hollywood-like recovery was planned where the returning capsule would be plucked out of the air by a helicopter as it gently drifted to earth under a parafoil (like a parachute, but directional).

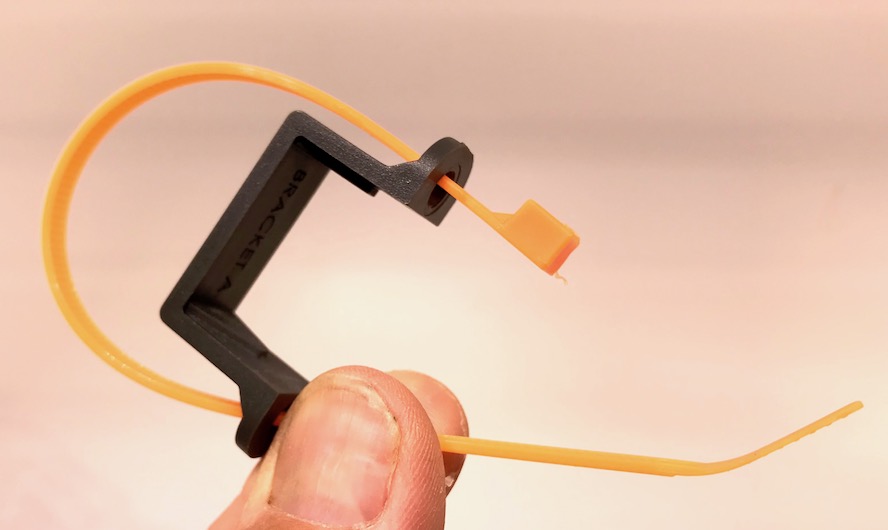

Remember Murphy? Well, the plan was for the capsule to detect a change in acceleration as it slowed due to the resistance of earth’s atmosphere to the tune of 27 g. A drogue chute would automatically launch stabilizing the capsule until the main chute deployed. The whole system would begin when a small acceleration sensor said it was time. Unfortunately that sensor was installed backwards thus preventing the capsule of fragile glass-like disks from making any attempt to slow down. The Genesis capsule slammed into the Utah desert while traveling 193 miles an hour.

But wait, there’s more. Meanwhile, another sample return was on its way home, a capsule full of STARDUST, well, comet dust actually. But the mission was named STARDUST. The plan here was for the capsule to eject from the main spacecraft, fly through the atmosphere as the fastest man-made thing ever, then gently land in Utah under a fully deployed parachute. Except that the STARDUST sample return capsule contained the same accelerometer as did the Genesis capsule. Luckily the documentation of the construction of the STARDUST capsule showed the correct orientation of the accelerometer and STARDUST make a picture-perfect landing even doing a “NASCAR” victory lap upon landing.

Now imagine yourself in role of accelerometer installer. Which direction will the sensor experience the necessary force to activate the drogue parachute when the capsule encounters atmosphere? Not so easy is it? Now attach a few hundred million dollars to your decision and suddenly it’s a really big deal to get it right. Not just some chimpanzee on a rocket sled or a man in a centerfuge anymore.

The Vernier Go Direct Acceleration sensor, with its onboard battery and bluetooth radio makes an amazingly powerful package that is only 26 grams and 30 cubic centimeters or about the size of a pack of gum.

And more information can be found in the user manual here.

Vernier lists the specifications as:

11 measurement channels:

- X-axis acceleration (m/s2)

- Y-axis acceleration (m/s2)

- Z-axis acceleration (m/s2)

- X-axis acceleration – high (m/s2)

- Y-axis acceleration – high (m/s2)

- Z-axis acceleration – high (m/s2)

- X-axis gyro (rad/s)

- Y-axis gyro (rad/s)

- Z-axis gyro (rad/s)

- Altitude (m)

- Angle (°)

- Range:

- Low acceleration: ±157 m/s2 (±16 g)

- High acceleration: ±1,960 m/s2 (±200 g)

- Gyros: ±2,000 °/s

- Altimeter: –1,800 m to 10,000 m (-5,900 ft to 33,000 ft)

- Angle: ±180°

Take a moment and consider those specification. A 10,000m altimeter? That much taller than Mt. Everest. And 200 g’s is plenty to kill a human four times over. However bacteria has survived over 400,000 g’s so don’t expect this sensor to capture the moment of g-force death of your E. Coli. But do expect it to do just about anything else you and your students can dream up.

Ad Astra!

Disclaimer: The views expressed in this blog post are those of the author(s) and do not necessarily reflect the official position of the National Science Teaching Association (NSTA).