feature

Learning Business Economics and Fermentation by Developing a Method for Producing Yogurt

Science Scope—July/August 2020 (Volume 43, Issue 9)

By Tahl Zimmerman, Tim Goetz, and Salam A. Ibrahim

CONTENT AREA Microbiology and Economics

GRADE LEVEL Middle school

BIG IDEA/UNIT How micro-organisms can be used to create food products

ESSENTIAL PRE-EXISTING KNOWLEDGE None

TIME REQUIRED 2.5 hours a day for 2 days

COST Cost varies depending on whether classroom has an incubator ($300), which is about half the cost of implementing the activity.

SAFETY Lactose-intolerant students should not taste the yogurt. Yogurt made in the labor-atory should not be eaten.

Yogurt can be used as a model for introducing students to the fields of microbiology (Drake and McKillip 2000), food chemistry (Zimmerman et al. 2019), and food production. When learning some basic principles about the bacteria behind fermentation, students can also learn about bacterial function and how bacteria can be used for positive ends (Kiefer et al. 2018).

Students involved in the Micro-Economy program at Greensboro Montessori School (GMS) experiment with practical life experiences in preparation for later life work. By participating in the program, middle school students engage in meaningful work that builds skills, encourages mutuality and interdependence, and fosters intellectual curiosity. As participants in the program, students consider various possibilities for producing a novel menu item for the school restaurant and a product to be sold at Maria’s Market, run by the school. Learning how to make yogurt fit both requirements, and with guidance from the instructors, the students learned how to produce yogurt within the constraints of a school day.

Following the predict-observe-explain (POE) structure of hands-on learning experiences (White and Gunstone 1992), students developed a culturing protocol in which they predicted and tested the outcome of yogurt production under different conditions. During this “science” phase of the activity, students resolved two issues: (1) how to produce yogurt within the time constraints of a school day by determining the ideal fermentation time and (2) what is the ideal type of milk to use as the starting ingredient.

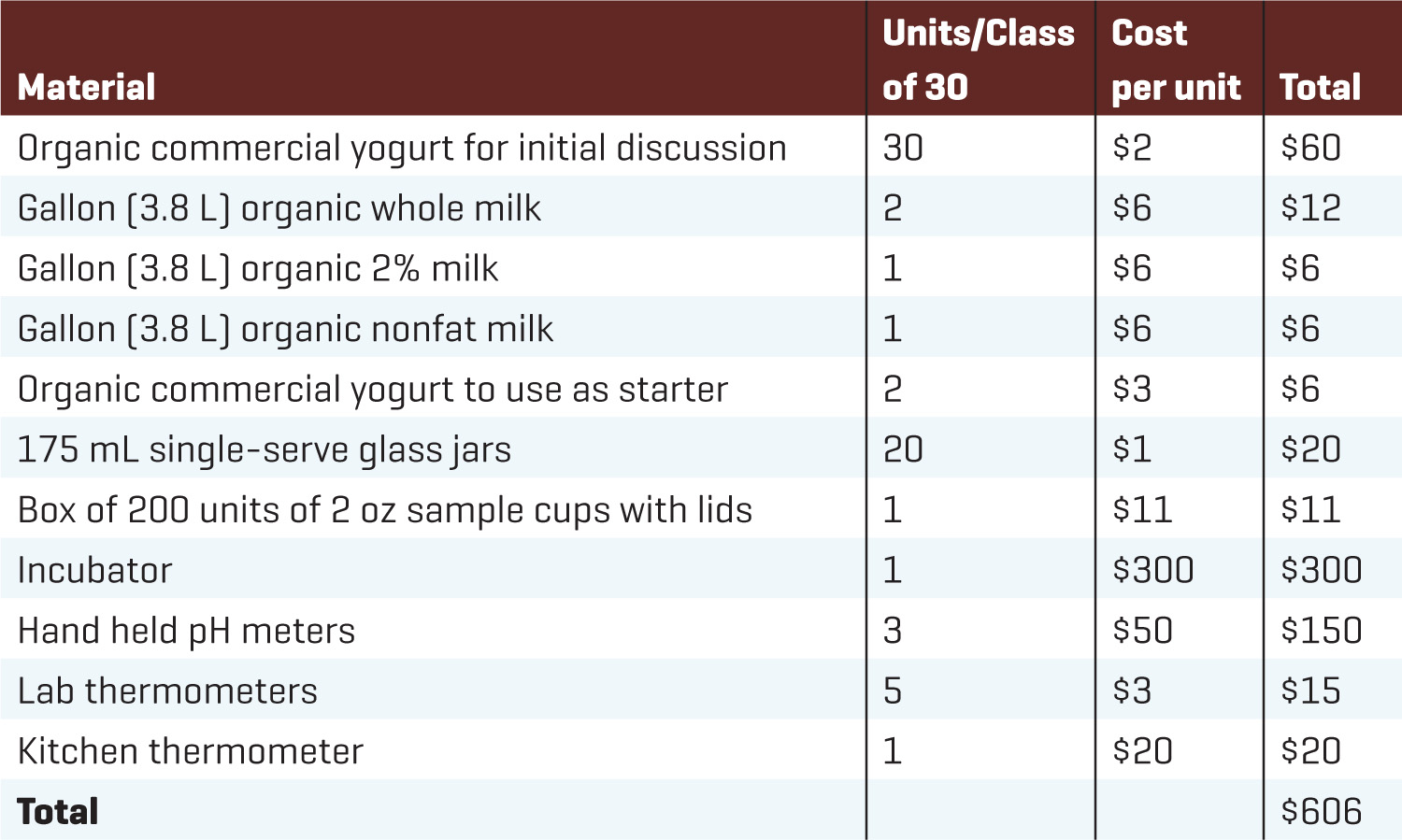

One of the goals of student groups participating in the Micro-Economy program is to make a reasonable profit to be reinvested back into the GMS community to fund future research, special school events, and field trips. Therefore, in a “business” phase students developed a business plan for how to produce and sell yogurt as well as a scaled-up procedure to produce yogurt for commercial sale. The students then began batch production of yogurt in the school kitchens, and the yogurt was “sold” to the cafeteria program to be served to fellow students and teachers as part of the internal economy of the school. Final products were also sold to parents via the school’s external market as a way of raising funds. The business plan required a calculation of the cost of milk, yogurt starter, and containers, and in this way, the activity also created an intersection between food design, business economics, and product development (see cost chart in Figure 1).

Cost chart.

We describe here the activity for developing a method to produce yogurt within a school day and for learning to transform basic and empirically derived scientific knowledge into the design of a food product. Student consumption and distribution of the yogurt can also be contemplated if the students have access to a licensed kitchen; however, this is not required for implementing the activity.

Health and safety

Fermented foods are safe to eat, and the bacteria used to produce them are generally recognized as safe. Materials used (milk, yogurt) were purchased from a local supermarket and should be considered safe. Yogurt produced in the laboratory should never be tasted and should be discarded after being analyzed. Protocols were developed in the laboratory and then adapted for use in a school kitchen licensed to prepare food for consumption. Kitchen production was supervised by the instructors and the kitchen manager, and food safety rules, such as washing hands and using a sanitizer on all kitchen utensils before use, were followed (see Appendices in Online Supplemental Materials). Please consult the food handling regulations as they apply in your state before considering producing yogurt for sale (see Resources).

Background information for Teachers

The optimum growth temperature of Lactobacillus bulgaricus and Streptococcus thermophilus, the two primary species used in yogurt cultures, is 40–44°C and 35–53°C, respectively (Sfakianakis and Tzia 2014). However, for the purposes of this activity, the term Lactobacillus is used as a stand-in for both species, with a standard culturing temperature of 40°C that is suitable for both species.

In a brief lecture students learned some facts about yogurt fermentation, such as Lactobacillus is a name that combines two terms: lactis (or milk) and bacillus (or rod). The first term refers to the use of this bacteria in milk, and the second term refers to the shape of the bacteria as seen in a microscope. The bacillus shape contrasts with the coccus (ball) and spirillum (spiral) types of bacteria.

Bacteria grow and reproduce in a process known as binary fission. Binary fission of Lactobacillus bacteria takes roughly 1 hour at 40°C, so it is possible to calculate how many cells result if the initial count of cells are known (Wilkinson and Booth 1986). Growing bacteria in a medium is known as culturing, and the conversion from milk to yogurt by bacteria is known as fermentation, as is the conversion of any food to another via the use of microorganisms (grapes to wine, cabbage to sauerkraut, etc.; Board 1983). Lactobacillus consumes lactose, the sugar found in milk, and produces lactic acid and acetaldehyde, the chemicals responsible for the sour and bitter tastes, respectively (Gezginc et al. 2015). An individual bacterium can be considered a tiny lactose-consuming factory. As the lactose gets consumed, the sweet taste is lost in the final product.

The two primary proteins in milk are whey and casein. As lactic acid is produced, the pH decreases. pH is a measure of acidity or “sourness.” The lower the pH, the more acid a liquid is. The more lactic acid produced, the more acid, or “sour” a liquid is. As the pH drops, via production of lactic acid, the casein “clump” together, or aggregate (Sfakianakis and Tzia 2014). This clumping is the process that is primarily responsible for the creamy texture of yogurt (Sfakianakis and Tzia 2014).

To prepare the milk for fermentation into yogurt, the milk is first heated to 90°C for 10 minutes. This has a twofold purpose: (a) to remove all competing bacteria so that the final product contains only the bacteria of interest, and (b) to aid in the aggregation process of the casein proteins (Sfakianakis and Tzia 2014).

Development of laboratory procedure

Part 1: Discussion and background information (30 minutes)

Students tasted samples of plain, unsweetened, lactose-free, commercially prepared yogurt (lactose-free yogurt was selected in case a student was lactose intolerant). Students were prompted to describe how the yogurt tasted. Creaminess, bitterness, and sourness were adjectives offered by the students. Students were then asked to consider what yogurt was made from. All the students knew that the source material was milk. Students were then asked to list the components of milk: water, protein, calcium, lactose, fat, vitamin A and D. What followed was a discussion of the nutritional aspects of each of these components. This was followed by a lecture about yogurt production and bacteria, which revealed that Lactobacillus bacteria is grown in milk to produce yogurt and that the lactose in milk is the source of energy for this bacteria. In addition, the students received information about how and why the chemical components of yogurt differed from that of milk (see Background Information for Teachers in callout box).

Part 2: Method development and implementation (2 hours)

The instructor asked the students if they would like to make yogurt and received enthusiastic positive replies. The students were then prompted to use the information learned in Part 1 to design a method for culturing yogurt. On a worksheet, students listed the materials and methods they thought were necessary to produce yogurt, as well as a set of procedures and outcome predictions (see Figure 2; also see Appendices in Online Supplemental Materials).

Students collectively work out a tentative procedure for yogurt production.

When designing the procedure, the instructor used the following prompts to aid students in developing their procedure:

- How much milk should we use?

- What temperature should we heat it to?

- Should we add the Lactobacillus after heating to 90 degrees?

- To what temperature should we lower it? Why? How much yogurt starter shall we add?

- Should we leave the yogurt culture of milk + yogurt exposed to air?

- Why or why not?

- At what temperature will the fermentation work best?

- Once it is done incubating, where should we store the newly made yogurt?

Next, the students asked where they would get the Lactobacillus. They were then asked to think about where they might find it. One student suggested that they use an “old” yogurt or the commercial yogurt. The instructor suggested that a 5% weight/volume of yogurt to milk contained sufficient amounts of Lactobacillus to ferment the milk into yogurt.

The instructors rarely intervened to state what the procedure for the yogurt-making should be, but relied on student answers to prompts to guide the method development until the students were left with two open questions: (1) What kind of milk should be used? and (2) How much time does the culturing take? With help from the instructor, the students collectively constructed the following tentative procedure:

- Heat 500 mL of some type of milk in a beaker on a hot plate for 90°C for 10 minutes.

- Cool to 40°C using a container of iced water.

- Add 25 g of commercial yogurt to the milk.

- Cover the beaker with aluminum foil.

- Place beaker in incubator at 40°C × number of hours. Note: a suitable incubator will have a temperature range of room temperature to 60°C and does not need to have a capacity of more than 0.75 cubic feet (20 L).

- Cool beaker overnight in a refrigerator.

For question 1, the instructor asked students to predict what would happen if the culturing took place with each kind of milk: nonfat, 2%, and whole milk. One student proposed that because whole milk was fattier, the resulting yogurt would be creamier and taste better. The students were then split into groups of three to four students, with each group choosing the kind of milk they would like to test (nonfat, 2%, or whole). Because all the students highly favored whole milk, at least one group was assigned to use nonfat and another group to use 2%.

To answer question 2 (How much time does the culturing take?), the students designed an experiment in which the inoculated milk would be placed in the incubator after being divided into plastic cups. The cups would be taken out at different time points and placed in the refrigerator overnight to be assessed the next day. The students suggested three time points: one, three, and five hours. The instructor then suggested an eight-hour time point (six hours is the minimum under these conditions to achieve the typical yogurt-like texture). The students were asked to make predictions about the yogurt, such as what would be the outcome with different kinds of milk, how the pH would change over time, how the creaminess would change over time, and how sour the yogurt would be over time.

At the end of the yogurt preparation, they measured the pH of the yogurt as a stand-in for sourness. Creaminess was ranked on a scale of 1 to 5, with 1 being the least creamy and 5 being the most creamy. A volunteer from each group recorded the pH data using a pH meter or pH strips. All final products were discarded after testing. The culturing process was repeated on a different day, and the students found the ideal incubation time to be six hours, taking into account the duration of the school day. Therefore, the final procedure read:

- Heat 500 mL of whole milk to 90°C in a beaker on a hot plate for 10 minutes. (Measure the milk using the gradations on the beakers. Use safety goggles and insulated gloves when handling hot liquids. Keep the hot plate away from the edge of the table.)

- Cool beaker to 40°C using a container of iced water in a Styrofoam container that can hold a 500 mL beaker.

- Add 25 g of store-bought yogurt to the milk and stir.

- Cover the beaker with aluminum foil (label with type of milk).

- Place in incubator at 40°C for 6 hours.

- Cool overnight in a refrigerator.

Health Note: It is important to emphasize that the yogurt produced in the classroom laboratory should not be consumed and certainly should not be sold. The classroom laboratory exercise provided the students with the information they needed to proceed to batch production in the school kitchen. Only yogurt produced in a school kitchen can be considered safe for consumption. In addition, instructors should ascertain if there are students who have lactose intolerance before allowing students to consume the kitchen made yogurt.

Part 3: Initial development of business plan (30 minutes)

The students then calculated the cost of production in materials, time, and space and calculated how much to sell the yogurt for at a reasonable profit. They considered the cost of containers, source yogurt, milk, single serve jars, and bulk containers. A lively discussion followed on how the restaurant program could use the yogurt (for sauces, desserts, and dressings); how to incorporate foods from the school gardens for flavors; if the yogurt could be sold to parents; and if so, what system of distribution should be used.

The students scaled up the procedure that had been developed in the laboratory for use in the kitchen by increasing the volume of milk from 0.5 L to 6 L. Whole milk was used, since the students agreed that this type of milk gave the final product the best texture. The kitchen procedure was analogous to the laboratory one. Jars were used instead of laboratory beakers and a large cooking pot was used to heat 6 L of milk in this scaled-up procedure (see Figure 3). The students worked with the kitchen staff to follow basic kitchen food safety protocols including washing hands, sterilizing all kitchen utensils using a sanitizer, and using cooking thermometers.

Assessment

Formal and informal assessments of student engagement suggested that this was an effective learning experience that connected microbiology, food science, chemistry, and economics. Student reactions to the learning experience were positive (e.g., “This is a great way to make money for the community,” “I know we can sell this in Maria’s Market,” “My mom and dad would buy this”). Assessment of the product was purely informal: 30 cups of yogurt (with fruit and granola added) were passed out to students, staff, and school board members. Most were returned empty with a positive response about texture and taste (see Figure 4).

Conclusion

This exercise teaches many science concepts, such as the nature of bacteria, controlling the growth of bacteria and utilizing them for positive ends, and the link between science and society. The learning environment already in place at GMS was particularly fertile ground for implementation of practical hands-on learning experiences of the type described here, therefore the impact of this activity on the school was high.

This exercise does not require the production of yogurt for sale to be implemented. For example, the activity can be limited to testing different milks while leaving out the different incubation times and business planning sections, or the business planning can be implemented in a more hypothetical fashion (what if we wanted to sell yogurt?). The activity can be expanded as well to assess growth temperatures and to assess taste directly (sourness, bitterness) in the case that consumable yogurt can be safely produced. Also, it can be expanded to determine the ideal amount of starter culture to use and to actually produce starter culture from pure strains of yogurt producing bacteria. Further expansions can include product testing via customer surveys of final products to further extend the “real-life” aspects of the activity. In addition, we believe that this activity could be adapted as a high school–level engineering design challenge.

Tahl Zimmerman (tzimmerman@ncat.edu) is a senior research associate in Family and Consumer Sciences and Salam A. Ibrahim is a professor of Food and Nutritional Sciences, both at North Carolina Agricultural and Technical State University in Greensboro. Tim Goetz is the Junior High science teacher at the Greensboro Montessori School.

Biology Chemistry Middle School