Research & Teaching

3D-Printed Laboratory Accessories as a Conduit for a Multidisciplinary Undergraduate Research Experience

Journal of College Science Teaching—March/April 2023 (Volume 52, Issue 4)

By Ethan S. Quinn, Brian Sylcott, Nathaneal T. Green, Joi P. Walker, and Robert M. Hughes

Although undergraduate research experience has proven to have positive effects on student outcomes, such opportunities are not always widely available. Options can be especially limited for early-career engineering students who have limited research experience. One approach to addressing this issue is to partner engineering instructors with active research laboratories to build research experiences into general engineering courses. This article details a collaboration between engineering and chemistry faculty to develop a pipeline of interdisciplinary, research-based projects for second-year engineering students. Chemistry laboratories are a good fit for this approach because they require a wide array of machinery and hardware for experimentation. This work also takes advantage of recent trends toward do-it-yourself labware that has been used with increasing frequency in colleges and universities through expanded access to 3D printing labs. Specifically, we present 3D printing projects as a potential conduit between chemistry and engineering that can enable engineering students to use their design skills to contribute immediately to laboratory projects. Our findings show that this approach allows engineering faculty to meet course objectives while involving students in interdisciplinary research that offers tangible benefits to chemistry laboratories.

The National Academy of Engineering has argued that the ability to work well in a team will continue to be crucial for the success of future engineers (Azmi et al., 2018; Male et al., 2010; National Academy of Engineering, 2005). Likewise, the 2020 Association of American Colleges & Universities annual report cited “the ability to work effectively in teams” as the skill most highly valued by employers (Finley, 2020). Recent graduates have also recognized the importance of teamwork. When asked about competencies in their undergraduate education, students identified teamwork as one of the most important and one that could benefit from additional focus (Male et al., 2010; Passow, 2012). As the complexity of engineering has increased, so has the likelihood that engineers will work in teams with colleagues from outside their discipline. Such projects often require that engineers engage in the social process of collaboration and speak the various languages of team members. The engineering program accreditation board, ABET (2021, p. 9), has also encouraged a focus on teamwork by dedicating an entire assessment criteria to having graduates possess an “ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives.”

The project we discuss in this article grew out of a collaboration between chemistry and engineering, beginning with an undergraduate research student studying bioprocess engineering. The student became acquainted with the research mentor through a general chemistry course and began independent study in the mentor’s lab after the conclusion of the course. The student’s previous engineering coursework had exposed him to SOLIDWORKS (a 3D-modeling program utilized by many industry professionals and engineering students) and the potential for 3D printing through the university library. As a result, the engineering student brought a preexisting skill set to the chemistry lab. In addition to the 3D printing project described in this article, the engineering student eventually participated in a biocatalysis project in which he learned fundamental organic chemistry techniques. The student’s individual 3D print project led to the creation of a course-based module for engineering undergraduates. We propose this course-based model, which enables teams of engineering students to work collaboratively with research faculty on design problems, as a valuable tool for engaging students in undergraduate research experiences while bridging gaps between engineering and the natural sciences.

Although general science courses give engineering students a solid foundation from which to apply their craft, engineering students too often consider courses such as general chemistry a “necessary evil,” thus entering and exiting the course with little appreciation for the cross-disciplinary applications of chemistry and engineering. Previously, researchers found that introducing material science into only a few general chemistry laboratory investigations increased relevance to engineering majors (Demetry et al., 2002). We suggest that similar cross-disciplinary collaborations might be considered elsewhere as a means of helping students find meaning and integrate subject matter. There are known benefits of cooperative projects where one student group designs and builds a working device for another group, then gets feedback from their peers on the efficacy of their efforts (O’Connor et al., 2001). In this article, we describe a design project based on meeting the needs of a university research lab in chemistry. In this project, the chemistry professor assumes the role of a “customer” whom the engineering students are able to contact with questions throughout the design process.

3D printing: Access and benefits

In recent years, ease of access of 3D printing has risen dramatically (Coakley et al., 2014). For example, today it is possible for 3D printers to be purchased for in-home use at a reasonable price. Furthermore, as 3D printing capabilities have improved, so have its potential applications, ranging from the leisurely (e.g., to make toys, figurines, or models) to the advanced (e.g., to make mechanical components, medical models, and laboratory equipment). Printable laboratory equipment is of special interest to research chemists, as it can solve a variety of interrelated problems in the lab, including budgetary (equipment cost), availability (replacement parts for aging equipment), and ease of access (equipping teaching and research labs in underresourced areas). In particular, the cost savings associated with 3D-printed labware can be quite significant. In some cases, laboratory equipment that costs between hundreds and thousands of dollars can be 3D printed for a fraction of the retail cost. Another issue affecting research progress is the scarcity of specialized components for research instrumentation. When these critical components are back-ordered, research projects can grind to a halt. Thus, the ability to design and print equipment within a 2-day period can provide researchers with critical and custom components much faster than the delivery time from manufacturers. Numerous research groups are already taking advantage of the benefits offered by 3D-printed labware (Brennan et al., 2018; Cathey et al., 2019; Chen et al., 2017; Coakley & Hurt, 2016; Da Veiga Beltrame et al., 2017; Desai et al., 2016; Nguyen et al., 2016; Patrick et al., 2015; Salazar-Serrano et al., 2017; Sun et al., 2019; Walker & Humphries, 2019; Zhu et al., 2015). Examples range from adapters for the integration of smartphones into microscope systems to the fabrication of routine microtube holders (Coakley & Hurt, 2016; Hernandez Vera et al., 2016). In addition, 3D-printing methods can provide underresourced areas with access to critical components required for daily life (Baden et al., 2015).

Many students enter engineering programs with some interest or experience in 3D printing, making it a good entry point for research activities. 3D-print projects can provide opportunities to practice iterative design with quick turnaround of the design-build-test cycle. In this article, we demonstrate that essential laboratory equipment can be designed, printed, and implemented in the laboratory in a process led by interdisciplinary undergraduate researchers who have interests in engineering and optimization. These projects not only serve as an introduction to the chemistry or biochemistry lab but also provide lasting connections between science, technology, engineering, and mathematics (STEM) fields, and particularly between chemistry and engineering. As these projects were led by undergraduate researchers who consulted periodically with the research adviser about laboratory equipment needs, students were able to work mostly independently, a critical step in developing advanced problem-solving skills (Harsh et al., 2017).

3D-printed lab hardware: Solo undergraduate project

In consultation with a chemistry faculty member, the engineering student identified four basic lab equipment needs that could potentially be met by 3D printing: a stand for holding chromatography columns, replacement adapters for a swinging bucket rotor, a floating caddy for holding sample tubes during freeze-thaw cycles in liquid nitrogen, and a magnetic nanoparticle retrieval stand.

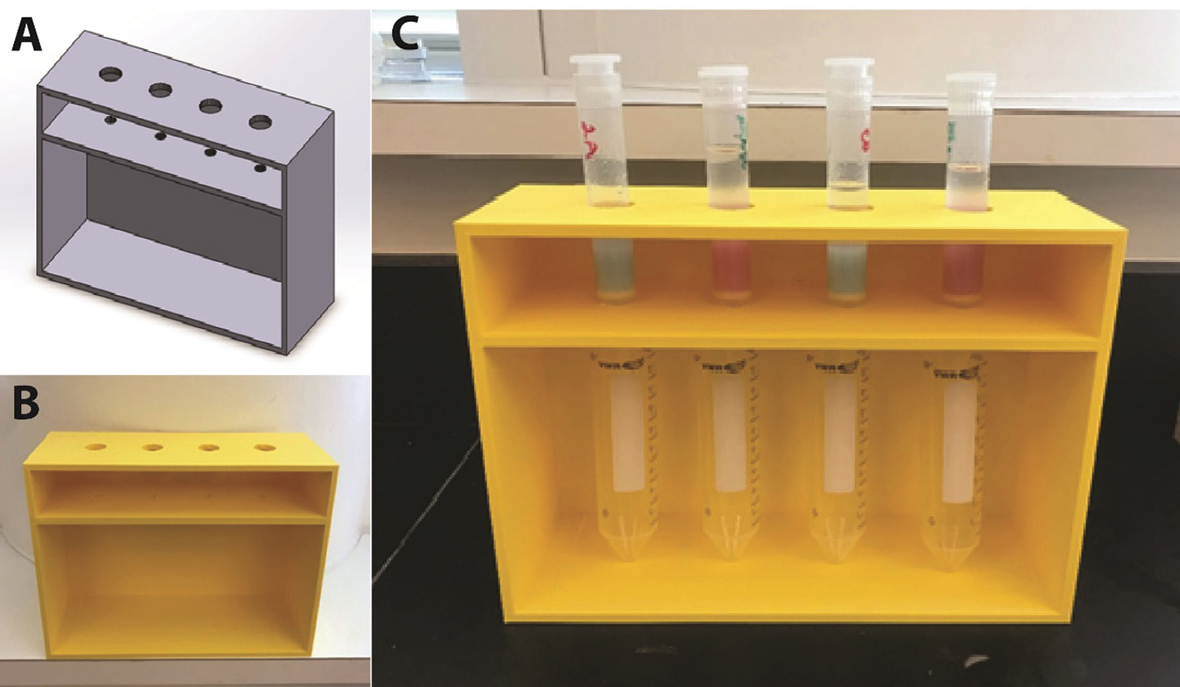

The first printing project, a column chromatography stand, was designed as a permanent replacement for a makeshift column chromatography stand that was crudely fabricated from a cardboard box. The original design was a major improvement over the cardboard stand, proving sturdy when exposed to aqueous solvent spills. However, the dimensions of the initial print prohibited the convenient placement of conical fraction collection tubes underneath the chromatography columns. The chromatography stand was redesigned and reprinted with dimensions that accommodated fraction collection tubes, allowing them to be placed upright beneath the chromatography columns (Figure 1). Printing this improved design cost $12.75, whereas a catalog equivalent costs more than $100.

Progression of a 3D-printed column chromatography stand.

Note. (A) Initial 3D model generated with the SOLIDWORKS modeling program. (B) Final 3D-printed design. (C) Final print with chromatography columns and collection vials.

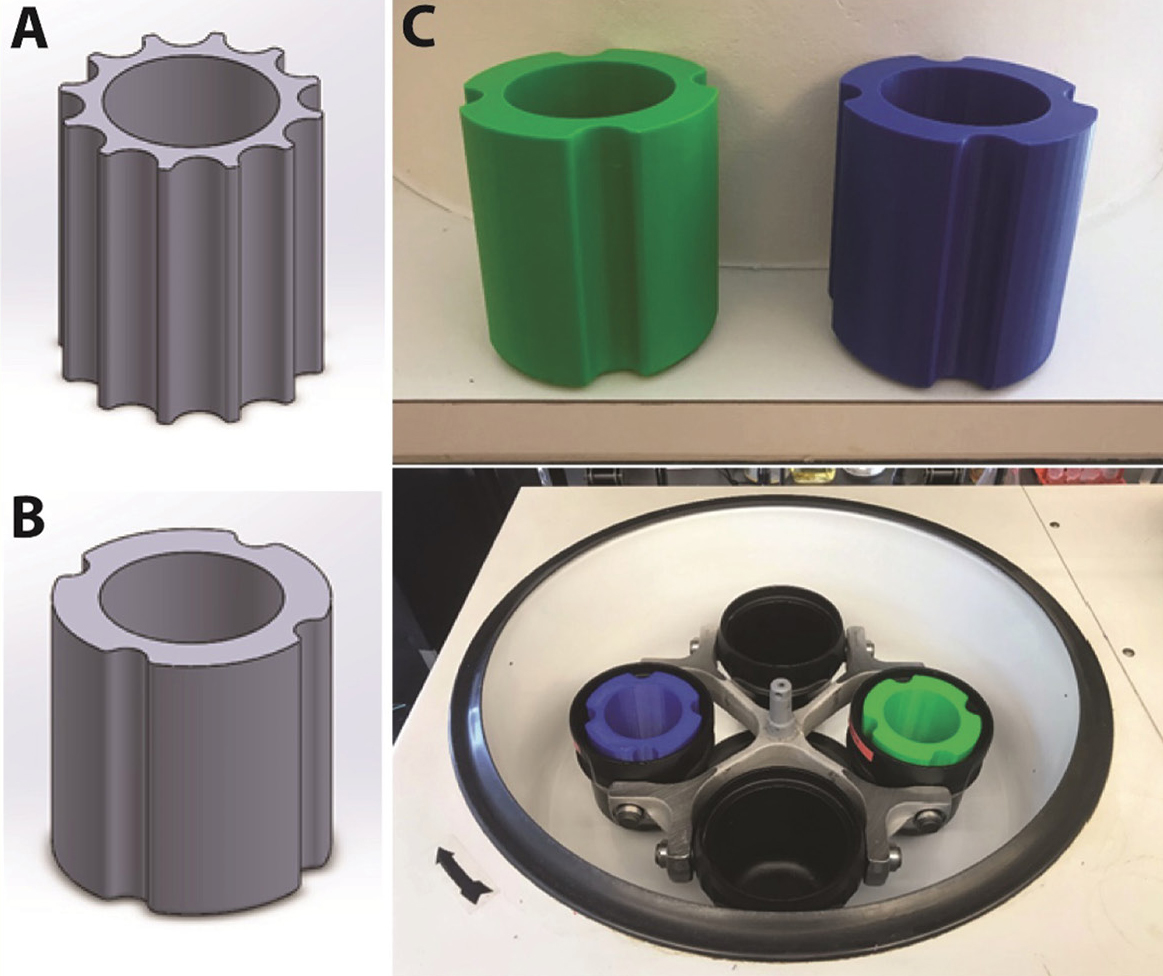

The second printing project was initiated to meet the laboratory need for two additional centrifuge bottle adapters (to accommodate 250 milliliter centrifuge bottles) for a Beckman GH-3.8 swinging bucket rotor. Analogous to the production of the chromatography stand, the 3D design and print process involved trial and error in the design and prototyping stage. The first design was modeled in SOLIDWORKS to mimic the manufacturer’s design as closely as possible (Figure 2A). However, the initial design failed upon reaching the maximum speed in the centrifuge, resulting in cracks in the bottom of the adapter and ultimately the detachment of the enclosed bottom. As a result of this structural failure, the initial design was reconfigured to meet the demands of centrifugation. The new design consisted of thicker walls, a filleted bottom outer–surface edge to better suit the rounded swinging bucket bottom, and elimination of the enclosed bottom surface (Figure 2B). This design was printed, tested, and confirmed as a workable prototype and ultimate final product (Figure 2C). The total cost to print one rotor adapter was $7, whereas new catalog equivalents cost approximately $500.

Progression of 3D-printed centrifuge adapters.

Note. (A) Original design generated with the SOLIDWORKS modeling program that ultimately failed under centripetal force. (B) Redesign of adapter updated with a hollow bottom to prevent cracking during centrifugation. (C) Final 3D-printed design alone (top) and installed in centrifuge rotor (bottom).

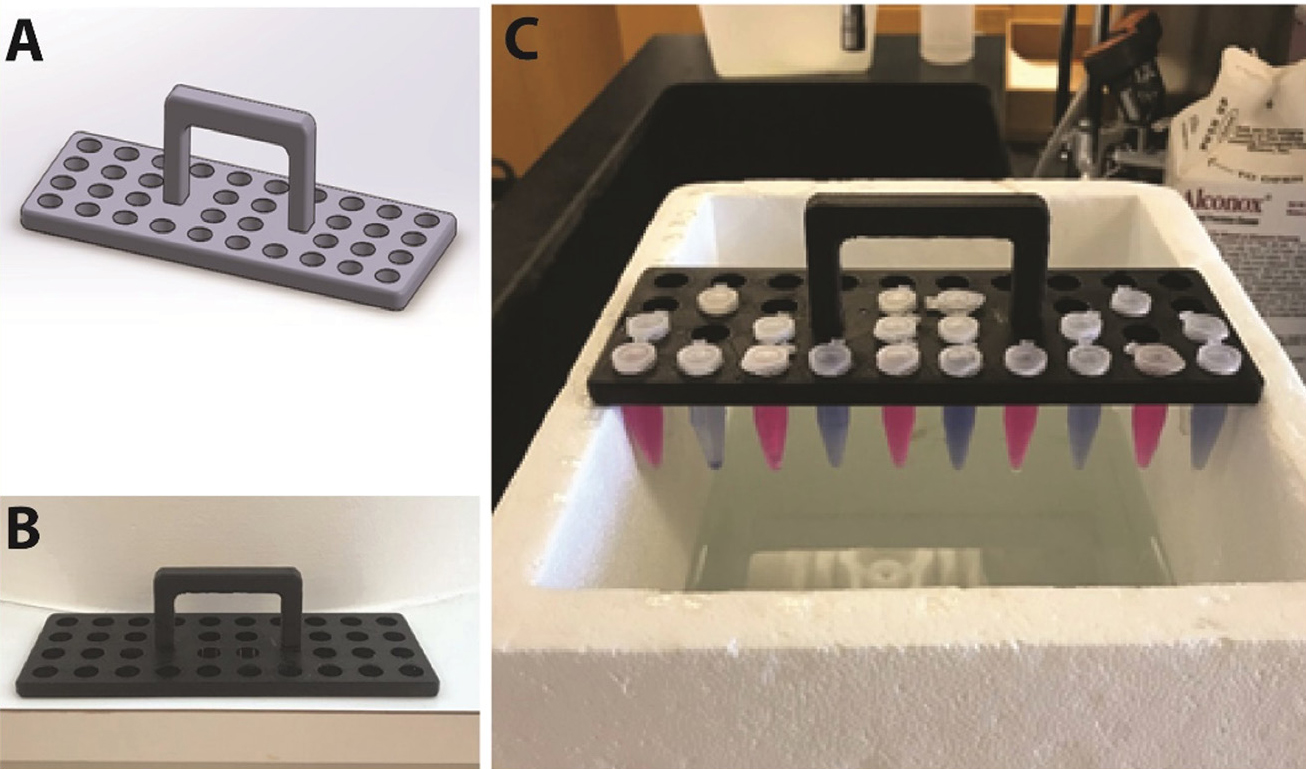

A third laboratory printing project stemmed from continual difficulty experienced during freeze-thaw cycles of samples in microtubes within a liquid nitrogen ice bath. Because there was no way to stabilize the samples, the tubes were either manually suspended using tweezers or tongs or dropped in the bath and then extracted individually. This was not a practical procedure for multisample freeze-thaw experiments, so it was decided that a new solution was needed. To meet this need, a tray or caddy was designed that would fit 36 microtubes (Figure 3A). The design incorporated a handle on the top for the purpose of simple and easy retrieval. Serendipitously, the plastic filament used to print the model is buoyant, allowing it to float atop the surface of the liquid nitrogen or water. This design also allows for simultaneous initiation and retrieval of freeze-thaw samples, reducing the time required to retrieve individual samples and potentially improving experimental reproducibility. The cost to print this design was only $3.25; no catalog equivalent has yet been identified for this custom labware (Figure 3B and 3C).

Progression of a 3D-printed microtube tray.

Note. (A) Original design created in the SOLIDWORKS modeling program. (B) Final 3D-printed design. (C) Final design with microtubes installed.

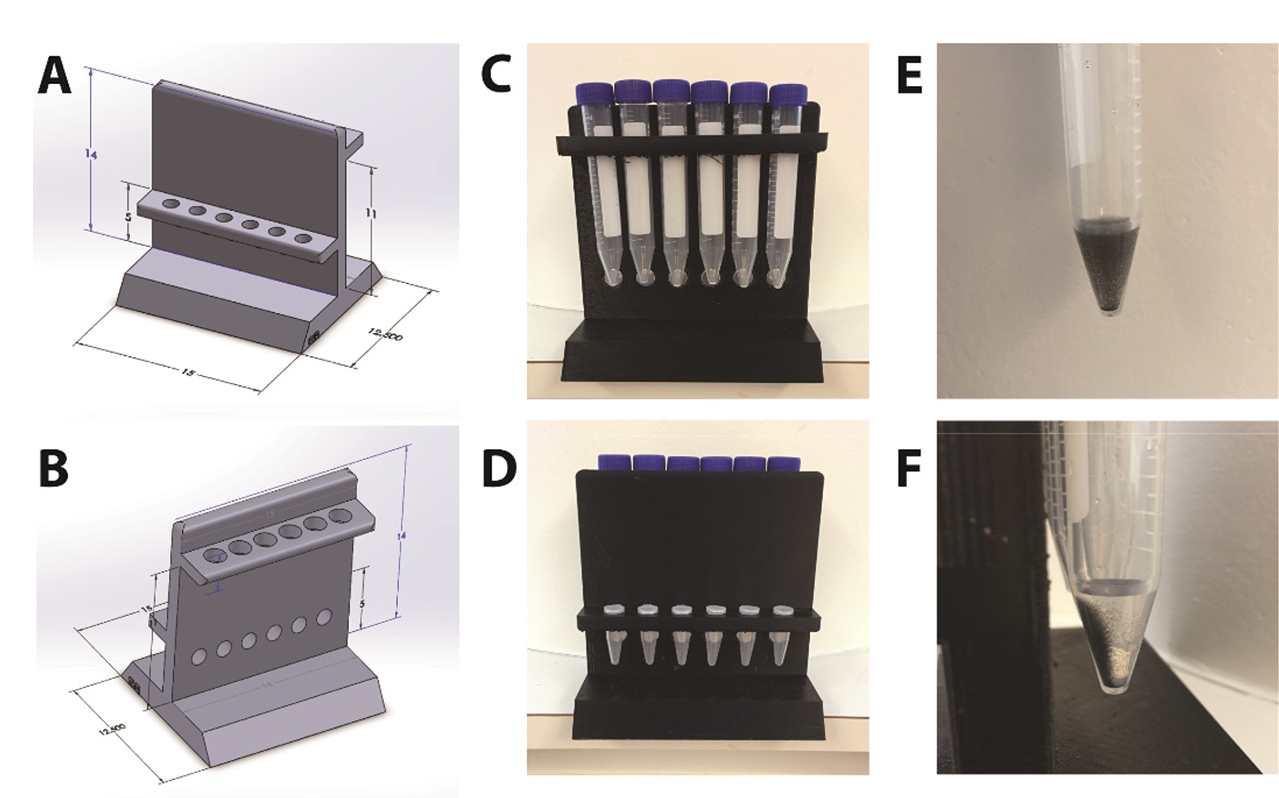

Finally, a stand for magnetic nanoparticle sample retrieval was identified as a fourth laboratory need, due to an ongoing research project involving magnetic nanoparticles. The current magnetic stand, obtained from a commercial vendor, accommodated only two 1.5 milliliter microtubes. Although this stand is useful in many small-scale operations, a device that can accommodate additional tubes and larger sample sizes was required. To meet this need, a magnetic separation stand was designed to accommodate six 1.5 milliliter tubes on one side and six 15 milliliter conical tubes on the other side (Figure 4A and 4B). The magnetic stand was designed with shelves located on opposing sides of the device at two different heights and with two different diameters of horizontally oriented holes. In addition, six vertically oriented holes were placed along the side of the rack to accommodate 0.5 inch x 0.5 inch neodymium magnets. The printed design functioned as intended, accommodating six tubes on each side (Figure 4C and 4D) and efficiently aggregating super paramagnetic iron oxide nanoparticles (SPIONs; Figure 4E and 4F). The cost to print this design was $13.50, whereas catalog equivalent prices range from $240 to $988.

Progression of a 3D-printed magnetic separation rack.

Note. Left panels show design created with the SOLIDWORKS modeling program. (A) The 1.5 mL tube side and (B) the 15 mL conical tube side. Dimensions are in centimeters. (C) Printed design with 15 mL conical tubes installed. (D) Printed design with 1.5 mL tubes installed. (E) Solution of superparamagnetic nanoparticles suspended in solution. (F) Solution of superparamagnetic nanoparticles installed on magnetic separation rack.

Design process and implementation: Solo undergraduate project

To create the designs, a prototype was first sketched by hand to approximate the proposed model, based on an initial consultation with the research advisor. In some cases, an existing piece of equipment in the lab was used as the basis for sketching a prototype (i.e., existing centrifuge adapters were measured to create a prototype for the 3D-printed adapters). Once a satisfactory sketch was developed, it was modeled in 3D form using the SOLIDWORKS program. The part files were then exported and subsequently printed at the 3D printing lab with staff assistance. As with most university makerspaces, several options for both 3D printers and printing filament were available. The scale of the printing project, the desired level of printing accuracy, time cost and raw materials cost, and the intended application environment (i.e., wet or dry, strength, stability) all factor in the choice of both printer and filament (see the online appendix for details). Ultimately, we selected the Fusion3 model printer and polylactic acid filament to print our designs.

Iterative design process: A route to proficiency and understanding

Each of the four laboratory hardware designs created for this study was tested for effectiveness and efficiency under routine laboratory conditions. In some cases, an iterative trial-and-error approach was required to obtain an optimized design solution. For example, the first design of the column chromatography stand (Figure 1) was functional but not tall enough to accommodate the height of the fraction collection tubes commonly used in the lab. The second design was adjusted to fit 50 milliliter conical tubes. This second design was successful in accommodating the conical tubes frequently used in the lab (Figure 1C). In addition, the first design printed for the centrifuge adapters (Figure 2) had a closed bottom and sharp unfilleted edges, modeled directly after the commercially available adapter that was on hand in the laboratory (Figure 2A). However, the 3D-printed material was not strong enough to withstand the force of the centrifuge while holding a fully filled centrifuge bottle. As a result, the bottoms of the adapters cracked during their first use and had to be discarded. The final print featured an open-end design with filleted edges to accommodate the curved bottom of the centrifuge swinging bucket (Figure 2B). This design did not crack during use (up to 3800 rpm) and has been in continual use for more than 6 months. For the freeze-thaw sample caddy (Figure 3), the original design was improved via the incorporation of a handle for easy sample retrieval. An iterative design process, in which students engage in optimization through trial and error, is a valuable learning experience for undergraduate researchers, where they learn that failure is a necessary (but often underemphasized) component of scientific progress (Linn et al., 2015). In addition, the relatively low cost of 3D printing facilitates iterative learning with minimal budgetary impact, whereas a similar approach in a wet lab using chemical reagents is often cost prohibitive, particularly for large groups of students.

Expansion of single student project to a course-based format

Using the single undergraduate research experience as a template, the 3D-printed labware initiative was expanded to a course-based format and implemented into an existing course titled Engineering Design and Project Management I. This is a 1–credit hour, project-based course required for all second-year engineering students. Although there was some lecture, most of the instruction time was spent having course participants work through the engineering design process in the context of three projects. The first two projects were each worth 20% of a student’s grade, and the third project, the design of 3D-printable hardware, was worth 30%. The remaining points were distributed between course participation and homework assignments. These activities took place in two separate course sections held during consecutive 8-week course blocks as part of a truncated instructional schedule created in response to the COVID-19 pandemic. In total, there were 18 student teams; each team was assigned one of six prompts. The prompts, which included the four projects described earlier in addition to two new, potentially more challenging design projects, are described in the following sections.

Project 1: A sample holder for performing multiple freeze-thaw cycles

Lysis of biological samples (i.e., bacterial and yeast cell pellets) is commonly done by performing multiple freeze-thaw cycles in liquid nitrogen. However, simultaneously freezing and thawing numerous samples can be quite cumbersome, causing experimental inaccuracies due to inconsistent freeze-thaw times. A caddy that securely fits sample tubes (1.5 milliliter and possibly even 15 milliliter conical tubes), floats on the surface of liquid nitrogen, and has a handle for rapid retrieval would be a time-saving tool in the research lab.

Project 2: A holder for protein

Small-scale protein chromatography is a common procedure in biochemistry labs. Various protein manipulations (e.g., purification, buffer exchange, size-exclusion chromatography) can be performed using various resins in a fritted plastic column. Although these columns are relatively inexpensive and typically reusable, the commercially available acrylic stands that hold the columns in place are expensive. Designing a multicolumn stand equipped with a removeable reservoir for emptying column waste and flow through would be a time- and money-saving apparatus for most biochemistry labs.

Project 3: Adapters for swinging bucket centrifuge rotors

Adapters for swinging bucket centrifuge rotors are used to hold 15 and 50 milliliter conical tubes securely in place during centrifugation. In our lab, we purchased a refurbished centrifuge that came with only two adapters for each type of tube. Having additional adapters on hand would enable simultaneous centrifugation of additional samples. In addition to saving time, a 3D-printed adapter would offer significant cost savings compared with the commercially available adapter.

Project 4: A magnetic separator stand for 1.5, 15, and 50 milliliter conical tubes

Magnetic beads (nanoparticles) are commonly used in biology and biochemistry labs for the separation and purification of proteins and other biomolecules. However, these stands are expensive to purchase, and rarely do commercially available stands accommodate tubes larger than 1.5 milliliter in size. A custom 3D-printed magnetic separator would enable the processing of samples both large and small. Superstrong neodymium magnets (available readily through online distributors) can easily be purchased for incorporation into the magnetic stand design.

Project 5: A solar- or spring-

Numerous protocols in the physical sciences (and clinical lab work) involve the incubation of samples with rotation. Commercially available rotors vary in their rotational modes (e.g., end-over-end vs. Ferris wheel) and use electric motors. A 3D-printed lab rotor than runs on solar or spring (i.e., wind-up) power would be a “green” alternative, also potentially enabling sample processing in medical labs with limited access to the power grid. Adaptability to multiple tube and sample sizes would be a plus.

Project 6: A hand-, solar-, or spring-powered centrifuge

Numerous protocols in the physical sciences (and clinical lab work) involve the centrifugation of samples. Commercially available centrifuges vary widely in size and expense and use electric motors. A 3D-printed centrifuge than ran on solar, spring (i.e., wind-up), and hand-crank power would be a “green” alternative, also potentially enabling sample processing in medical labs with limited access to the power grid. Adaptability to multiple tube and sample sizes would be a plus.

In addition to these prompts, students were also provided with addresses for websites with several 3D-printed and do-it-yourself examples of laboratory hardware as potential sources of inspiration (see the online appendix). Students were also provided with the contact information of the “customer” (the chemistry faculty member) and encouraged to contact them with any questions, including those related to design, dimensions, and material requirements for the devices.

Results

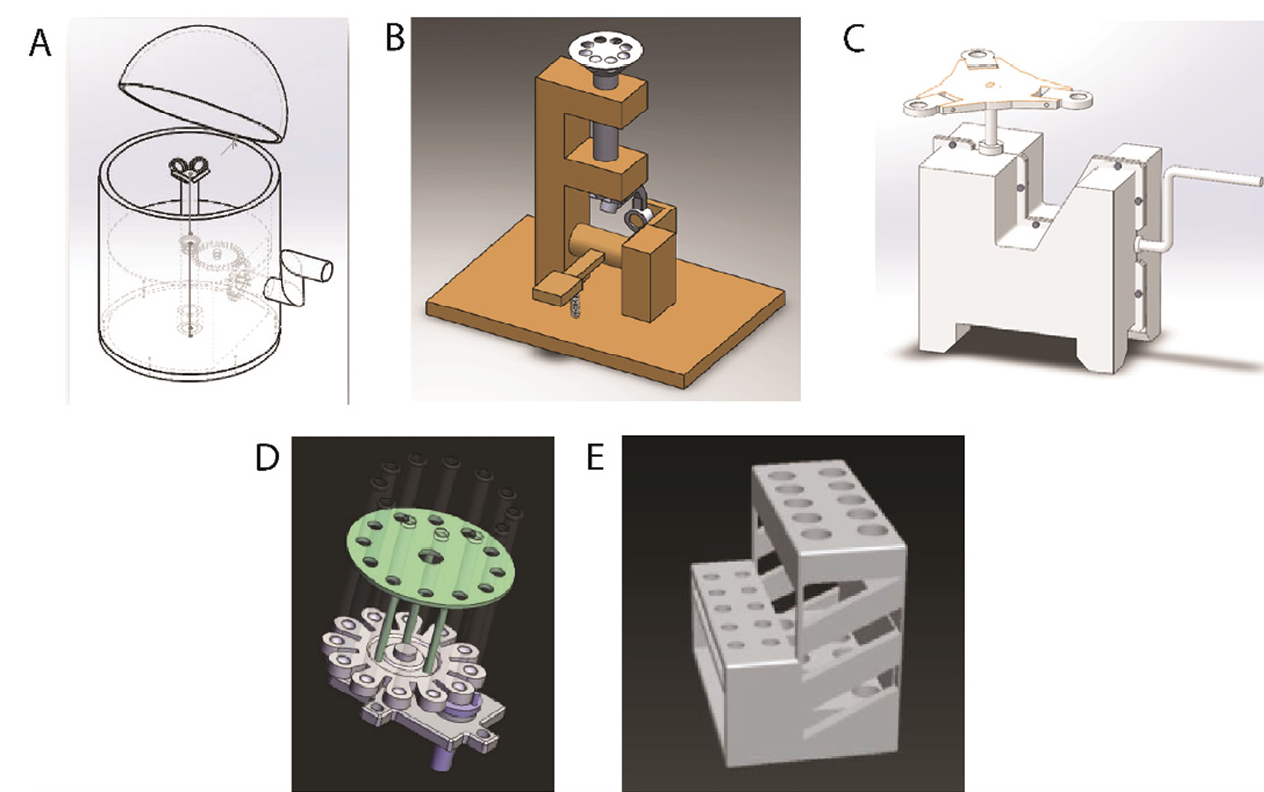

As part of their assessment, each team submitted a design report and engineering drawings of their design. Project reports were submitted in an engineering format with sections including Problem Statement, Ideation, Gantt Chart Timeline, Design Selection, Design Decision Matrix, Final Design, and Economic Analysis (see the online appendix for an example of a student team report). Interestingly, final designs (see Figure 5 for examples) varied widely, indicating that student teams arrived at unique solutions, even when working from the same prompts.

Designs from engineering students’ team-based projects.

Note. Schematics of student designs for hand-cranked (A, C) and foot-pedal powered (B) centrifuges. (D) Schematic for a lab tube rotator. (E) Schematic for a multilevel column holder for chromatography applications.

Projects from this course are used as part of the engineering department’s assessment plan. ABET (2015, p. 3) requires that graduates demonstrate an “ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability.” Each project was evaluated using the rubric shown in Table 1. All 18 teams developed preliminary designs that addressed most of the considerations, but the shortened semester made it infeasible to test and iterate on these designs.

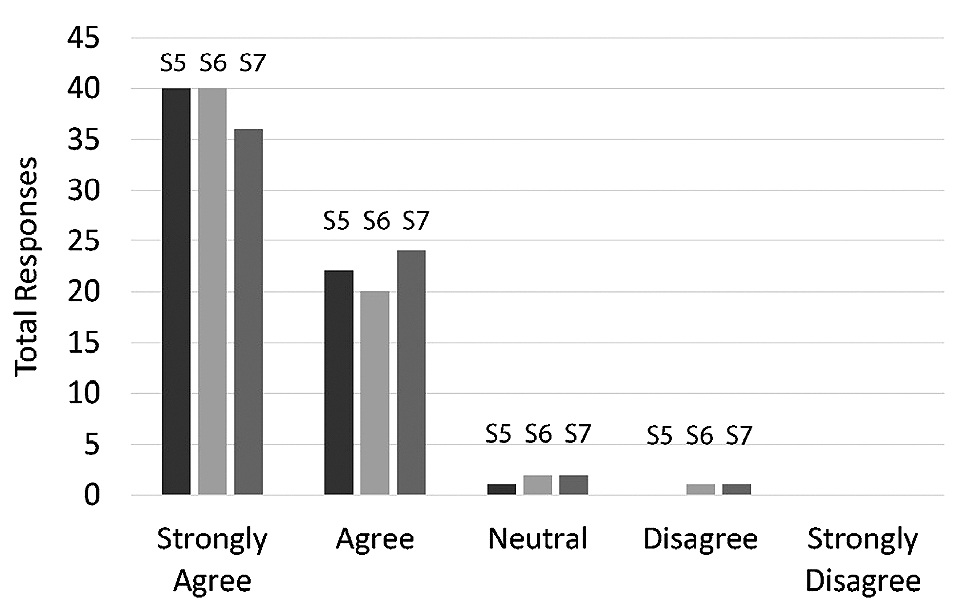

The assessment at the end of the semester also includes a survey using a Likert scale (see the online appendix). As part of the survey, course participants were asked to rate the following statements (on a scale from “strongly agree” to “strongly disagree”):

Out of 63 respondents, 62 (98%) indicated that they agreed or strongly agreed with S5, 60 (95%) indicated that they agreed or strongly agreed with S6, and 60 (95%) indicated that they agreed or strongly agreed with S7 (Figure 6). Although the results from these assessments are in line with those from previous years, in which no 3D printing and design module was used, they demonstrate that the introduction of the 3D print module did not disrupt the team-building process established by previous iterations of the course.

Student responses to Statements 5, 6, and 7 from end-of-semester surveys.

| Table 1. Grading rubric for final design | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

The potential upside of the proposed module was perhaps best captured by interviews with individual student participants after completing the 3D print module. For example, a reflection written by the undergraduate student who piloted the project implicated three primary areas in which they felt their skills had improved: improved efficiency and accuracy in the design process, increased understanding of the chemistry laboratory environment, and increased ability to work cooperatively with a team (see the online appendix for the full student reflection). In addition, interviews conducted with teams of students from the course-based module revealed the surprising insight that some of the team members had neither seen nor used a centrifuge prior to engaging in the project. Therefore, by participating in this interdisciplinary project, engineering students were introduced to important equipment and techniques that they might not have encountered otherwise, thus bridging a critical, yet unanticipated, knowledge gap.

Discussion and implications for teaching

As a result of the 3D-printed labware we have described, an undergraduate engineering major developed laboratory hardware as part of a problem-focused design pipeline. This approach was then extended to a course-based setting, enabling student teams to achieve the desired learning outcomes from their engineering course by working through a multidisciplinary research project and reaping some of the benefits of undergraduate research experiences.

Effective science research teams are rich environments that support the growth and development of scientists and engineers, improving targeted outcomes, publications, funding, and scientific breakthroughs. At the undergraduate level, however, students majoring in science and the related STEM disciplines are rarely able to take part in authentic research activities as part of a science team. Furthermore, this 3D printing project provides a conduit for developing a multidisciplinary research team composed of discipline-specific science researchers and engineering students. As many engineering programs require seniors to complete capstone design project, identifying suitable mentored design projects can become a significant challenge as student numbers increase (National Academy of Engineering, 2005). Connecting engineering students with disciplinary scientists has the potential to bring about new avenues for capstone design projects and bridge the disconnect that engineering students often describe with their science coursework.

Moreover, future studies could focus on identifying specific disconnects encountered by engineering students; these knowledge gaps could be the basis for establishing integrative standards and outcomes for engineers enrolled in basic science courses. This project has also opened discussions between the chemistry and engineering faculty regarding the general chemistry laboratory curriculum. Approximately one third of the students enrolled in the first-semester general chemistry laboratory have indicated that they intended to pursue an engineering major. The addition of material science as well as some design features to the lab activities will help with the perceived relevance of the course for the engineering students (Demetry et al., 2002). We also hope that such changes might increase interest in an engineering major for other students in the course.

This article also highlights the benefits of student engagement with community-based 3D printing laboratories available on many college campuses. By illustrating research enhancement through the utilization of a local 3D printing lab, we hope this project serves as a model for engaging beginning undergraduate researchers with engineering or design backgrounds in chemistry research labs. Ultimately, the significant cost savings associated with the 3D-printed labware may be useful for equipping underresourced teaching and research labs. For example, one might conceive of an entire high school chemistry lab curriculum in which the bulk of the nonconsumables could be produced rapidly with 3D printing technology. In this scenario, 3D-printed centrifuges, lab rotators, test tube racks, and other equipment generated on the fly would provide direct links between chemistry, materials science, and the engineering design process. This could represent an innovative approach to secondary science education.

Conclusions

Design projects, realized through the increasingly accessible medium of 3D printing, can serve as useful conduits for interdisciplinary collaboration between STEM fields. In the area of college science teaching, this can result in thought-provoking experiences for undergraduates that can fill unforeseen gaps in scientific understanding. There is also intrinsic value in the process of iterative design, which exposes students to unanticipated outcomes that require troubleshooting and formulation of creative solutions. Creation of a model process for integrating design, 3D printing, and interdisciplinary collaboration into an undergraduate setting has broad implications for the creation of alternative methods for enhancing undergraduate STEM experiences.

Materials and Methods

SOLIDWORKS software is a product of Dassault Systèmes. Access to SOLIDWORKS Education Edition was provided through the East Carolina University College of Engineering and Technology. Neodymium magnets (D88-N52) were purchased from K&J Magnetics, Inc. (Pipersville, PA). 3-D printing was conducted at the East Carolina University Joyner Library 3D Print Studio using polylactic acid (PLA) filament and a Fusion3 F400-S 3D printer.

Acknowledgments

We would like to acknowledge Mandy Nichols, technology coordinator at East Carolina University’s Joyner Library 3D Print Studio, for her supervision and assistance with 3D printing. We would also like to acknowledge Professor Hayden Griffin, PhD, for assistance with implementing the 3D print module in an engineering course and the students of ENGR 2000.

Ethan S. Quinn is a former undergraduate research student in the Hughes lab and is currently pursuing a Doctor of Philosophy at the North Carolina State University College of Engineering in Raleigh, North Carolina. Nathaneal T. Green is a former undergraduate research student in the Hughes lab and is currently pursuing a Doctor of Pharmacy degree at the University of North Carolina Eshelman School of Pharmacy in Chapel Hill, North Carolina. Robert M. Hughes (hughesr16@ecu.edu) is an assistant professor and Joi P. Walker is an associate professor, both in the Department of Chemistry, and Brian Sylcott is an associate professor in the College of Engineering and Technology, all at East Carolina University in Greenville, North Carolina.

Interdisciplinary Labs Makerspace Technology Postsecondary