Feature

Surveying the Safety Culture of Academic Laboratories

Journal of College Science Teaching—November/December 2020 (Volume 50, Issue 2)

By Emily Faulconer, Zachary Dixon, John C. Griffith, and Hayden Frank

The university traditionally has been the foundation for young adults’ professional development, yet the proclivity toward safety culture has garnered less focus in higher education than in the workforce. A survey of faculty at a medium-sized, research-active, private institution revealed specific areas of policy noncompliance as well as specific safety attitudes that can be targeted for interventions. Albeit a snapshot view, the survey implies that safety needs better representation in the classroom, teaching laboratories, and research facilities at universities. Safety is not abandoned by any means, and there is a strong presence of safety-oriented individuals, but the data show barriers to safety do exist that need to be addressed. The implications of this small-scale study serve as a foundation for a more comprehensive multi-institutional study in the future.

Many universities offer laboratory courses in support of science lecture courses. A laboratory experience offers the opportunity for students to interact with and manipulate instruments and materials in order to explore scientific theories. The National Research Council emphasizes the importance of maintaining student safety in laboratory settings (NRC, 2014). The U.S. Occupational Safety and Health Act (OSHA) governs workplace health and safety. Within this act, safety in a laboratory setting is addressed through the Hazard Communication Standard, the Laboratory Standard, and the General Duty Clause. These standards do not cover public sector workers or nonemployees such as students in a teaching laboratory (Stroud & Roy, 2009), though many states have OSHA-approved state plans that do cover public sector workers. Some states have safety statutes that are applicable to nonemployees such as students in academic labs. While many institutions adopted the Lab Standard for employees and students, it often replaced safety education for students to the detriment of both safety competency and safety ethics (Hill, 2012). Academic laboratory safety programs can benefit from adopting federal and industry safety standards such as those in the OSHA Process Safety Standard and the NIOSH Pocket Guide (Barsan, 2007; Langerman, 2009). Professional organizations also offer key resources, including the American Chemical Society’s report “Creating Safety Cultures in Academic Institutions,” the National Research Council’s Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards, and the National Science Teaching Association’s Safety Blog and Safety Issue Papers (Hill, 2012; NRC, 2011; NSTA, 2020).

Despite these guidelines, accidents do happen in higher education teaching and research laboratories. Many accidents are relatively minor. In a 2018 study, the most prevalent category of compensable accidents were cuts, lacerations, and punctures (32%); exposure to blood and body fluids through needle-sticks; animal bites and other mechanisms (25%); and chemical exposures (19%) (Gosavi et al., 2018). However, some lab accidents cause permanent debilitating injuries or are fatal (Carson, 2014; Gibson et al., 2014; Jia, 2016; Kemsley, 2016; Van Noorden, 2011).

Investigations into significant academic laboratory accidents reveal systematic safety failures (ISHN, 2011; Benderly, 2016b). Within the aviation, nuclear, and medical fields, there is abundant safety culture research, but less exploration of safety culture within higher education outside of these fields (Gutierrez et al., 2013; NRC, 2014; Schroder et al., 2016). While safety culture has a variety of definitions (Wiegmann et al., 2004), here we define safety culture as one in which all individuals feel responsible for safety, where employees proactively identify unsafe conditions and behaviors and intervene to correct them, and employers place the intrinsic value of individuals within the organization above their monetary significance.

The small collection of studies on academic laboratories reveal weak safety cultures (Ayi & Hon, 2018; Eldridge, 2012; Gosavi et al., 2018; Gutierrez et al., 2013; Van Noorden, 2011). Of practical significance, motivation, accident experience, and safety training significantly influenced safety culture and incidents (Cooper & Phillips, 2004; Ferjencik & Jalovy, 2010; Wu et al., 2007). The presence of a safety manager and a safety committee also influence safety culture (NRC, 2014; Wu et al., 2007). Moderating factors included gender, age/experience, and title (McEwen et al., 2018; Wu et al., 2007). For teaching laboratories, student understanding of safety can be used as a proxy for measuring safety culture effectiveness. Studies show students in teaching laboratories have deficient safety knowledge (Adane & Abejee, 2012; Al-Shuaili & Al-Muammari, 2010; Karapantsios et al., 2008). This could be addressed by embedding competencies in chemical safety information into the undergraduate curriculum (Sigmann, 2018).

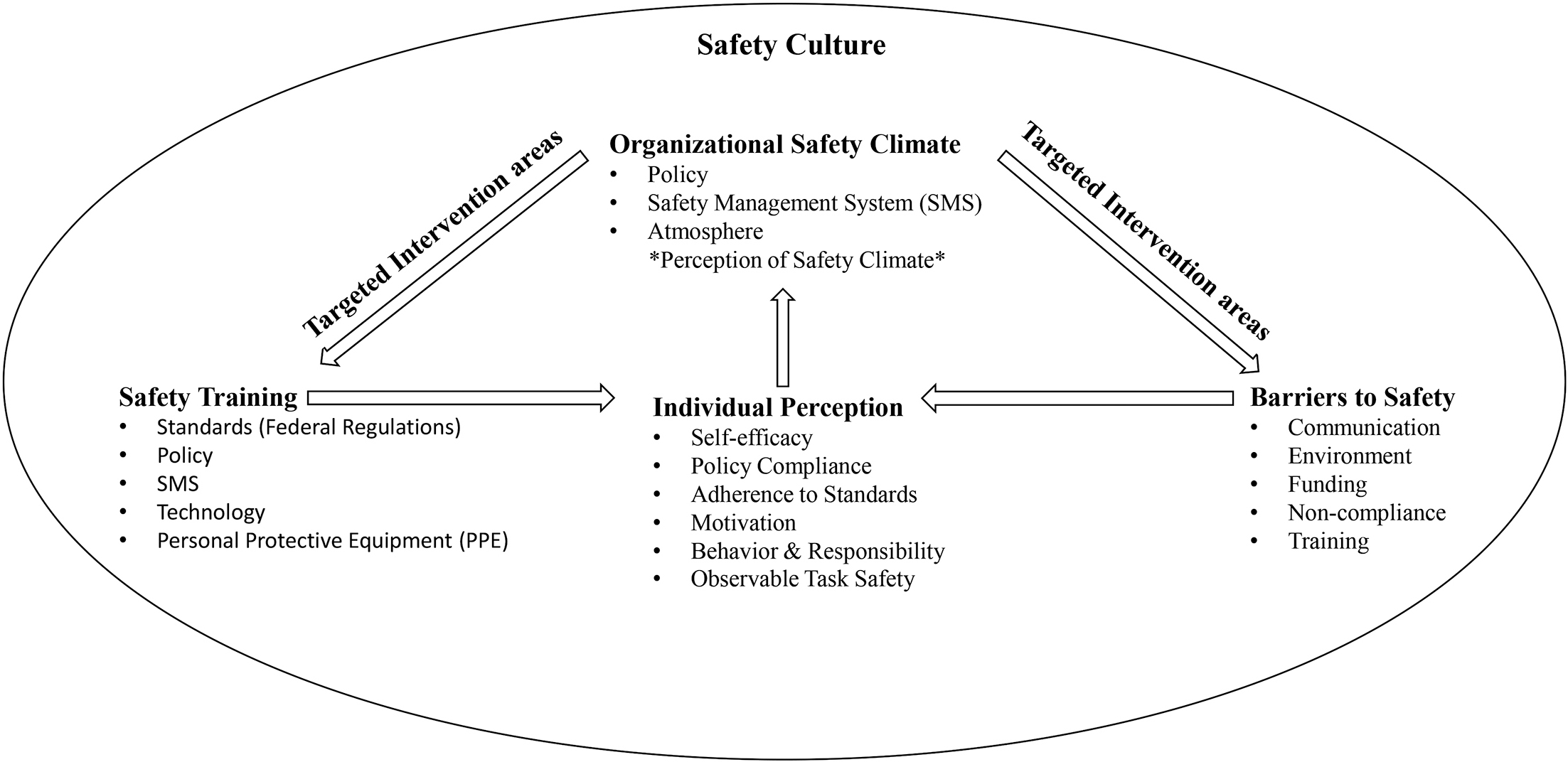

A proactive safety culture is generated through a core commitment to safety in all levels of an organization (NRC, 2014). Safety as a core value can be communicated many ways, including a nonpunitive reporting system and using safety in faculty performance reviews (Benderly, 2016a). Recognition of safety performance has been noted in safety culture surveys to be an area for growth (Gutierrez et al., 2013). Challenges to an effective safety culture include knowledge gaps, the hierarchical system in academia, and the unique safety considerations of research labs compared to educational labs (NRC, 2014). This is further complicated by the difficulty in changing safety behavior through interventions (Reniers et al., 2014). Figure 1 presents a theoretical framework for safety culture.

Safety Culture Theoretical Framework

It is clear that very serious safety concerns exist in academic laboratories. It is also clear that safety culture is complex. The purpose of this study is to contribute to the small body of work in this area by investigating safety culture at a research-active private university, specifically exploring several metrics of safety culture participation and self-efficacy. We hypothesized the following: 1.Less than 25% of the potential participant pool would respond to the survey. 2.Training has a positive impact on faculty self-efficacy regarding awareness and use of safety policies and procedures. 3.Belief that the organization is engaged in the safety culture at multiple levels has a positive impact on faculty self-efficacy regarding awareness and use of safety policies and procedures.

Material and methods

Data were collected from principal investigators (PIs) and laboratory supervisors (LSs) employed at a medium-sized, private university. Participants were selected using purposive sampling, targeting those who both meet the definition of a chemical worker and those who have PI or LS responsibilities. The institution has a Carnegie Classification of R3, a “moderate research” institution. Research activities at this institution garner both internal and external funding support.

Faculty were asked to complete a survey on their knowledge and perspectives regarding institutional safety culture. The survey was deemed exempt by the institutional review board prior to administration of the survey.

A cross-sectional survey was used, developed by faculty across multiple disciplines, including those with expertise in fire safety, chemical safety, and science communication. The survey tool consisted of 11 closed questions. QuestionPro was used to administer the surveys anonymously. Survey data were collected in spring 2019. Responses were voluntary. All survey data were treated as nominal. The number of respondents prevented inferential statistics; descriptive statistics were applied.

Results and discussion

Response rate

A hallmark of a strong safety culture is engagement (Nahrgang et al., 2011). However, as hypothesized, our survey was met with a low response rate. Of the 52 LSs or PIs identified in the sample institution, only eight responded to the survey device, resulting in a 15% response rate and confirming our hypothesis that less than 25% of the potential participant pool would respond to the survey. The lack of participation in this study from the potential participant pool indicates engagement as an important shortcoming of the sample institution’s safety culture.

Even from the outset of the study, faculty engagement in lab safety culture represented a problematic hurdle. As the research team prepared for data collection, it was found that the sample institution did not have an accurate or complete picture of its LS or PI population. No definitive list of LSs or PIs existed on a university, college, department, or program level. Without a definitive list of LSs or PIs, this study relied on three rounds of distinct solicitation: one by distribution of the survey devised through an institutional full-time faculty listserv; a second round distributed through college-level administrative staff; and a third distributed directly to LS and PI faculty identified by department chairs, program chairs, and other department-level administrative staff. In total, the research team contacted 42 department and program chairs, as well as other administrative staff, who collectively identified 52 faculty members as either LSs or PIs. The lack of institutional awareness of its critical laboratory personnel speaks to a foundational engagement problem. Without clear or accurate accounting of a lab population, it is difficult to engage that population in an institutional culture of safety.

During data collection, the research team also experienced confusion from institutional points of contact about what constituted a “laboratory environment” or “chemical workers.” Some contacts questioned whether or not their labs qualified for participation in the study. Some points of contact initially rejected our request to distribute the survey due to a perceived lack of laboratory spaces within that institutional division. This confusion about what constitutes a lab in which professionalized safety protocols are required represents something of an unexpected confounding variable in this study. The confusion expressed by college, department, and program contacts suggests there may be additional faculty whose labs and work qualifies them for participation in this study, but who were not identified or made aware or did not self-identify to participate, despite the key terms of “laboratory environment” and “chemical worker” being defined in the recruitment messaging. This observed confusion speaks to the problem of cultural engagement. Without accurate accounting of institutional lab personnel, communication about what conditions warrant professionalized lab safety practices is unlikely to disseminate adequately throughout that population. Without adequate communication of fundamental lab safety culture tenants and practices, faculty are unlikely to become or remain actively engaged in a culture of practice.

Training

According to OSHA, a Chemical Hygiene Plan (CHP) must address specific criteria, including but not limited to (1) the criteria an employer will use to determine and implement hazard control measures, including use of personal protective equipment (PPE) and hygiene practices and (2) methods and observations that may be used to detect the presence or release of a hazardous chemical, (3) physical and health hazards of chemicals in the work area, and (4) the measures workers can take to protect themselves from these hazards, including the use of PPE (OSHA, 2011b). While OSHA mandates training on the Lab Standard (and thus the CHP) at the time of appointment or when duties or hazards change, the institution studied here has mandated that Lab Standard training occur annually. Five of the eight respondents (62.5%) indicated they had been trained on the use of PPE in the last 12 months. Three respondents (37.5%) reported they had not been trained on PPE use, with one being employed over 12 months and two employed less than 12 months. As PIs and LSs, the respondents also have been delegated responsibility through the CHP for selecting appropriate PPE for an activity in their work area. The same distribution was reported for being trained on PPE selection, with 62.5% reporting adequate training. Despite the training deficiencies, all respondents indicated confidence in selecting appropriate PPE.

Two respondents (25%) reported being trained on the institution’s CHP within the last year, while one (12.5%) reported training in the last five years. Five faculty (62.5%) reported never being trained on the CHP, with two being employed for more than 12 months. Institutional policy mandates initial training with annual refresher training, meaning 37.5% of faculty were noncompliant. Training covered key concepts including the digital location of the CHP and Safety Data Sheets (SDS), the presence of an anonymous safety reporting system, the institutional hazardous waste (HW) disposal procedures, and key points of contact for safety within the institution. Respondent knowledge of each was explored in the survey (Table 1). While only half of the respondents had been trained on the CHP, the majority knew how to access the electronic SDS. The response rate was too low to reliably report correlations between receiving training and responses on the key aspects of training.

| Knowledge of key aspects of training. | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Of substantial concern is the lack of knowledge of an established procedure for the handling and disposal of hazardous waste. The Resource Conservation and Recovery Act (40 CFR 262.17[a]) mandates that hazardous waste personnel at large quantity generators (LQGs) are trained, at a minimum, to ensure facility personnel are able to respond effectively to emergencies involving hazardous waste (EPA, 2016). Failure to meet these training requirements can result in civil and criminal penalties. Training must occur within six months of job placement and retraining must occur annually. Half of the respondents reported training within the last year. Another 37.5% reported no training, but employment less than 12 months. Only one respondent (12.5%) was clearly in violation of this training mandate, reporting training within the last five years. Only 57% of respondents indicated an established procedure for handling and disposal of hazardous waste. The sample size prevented reliable analysis of correlations, however, there are some interesting potential relationships. While knowledge of HW disposal procedures did appear to correlate with training, confidence in making HW determinations did not appear to correlate with training. Similarly, there did not appear to be a correlation between those who identified a standard procedure for handling HW and those who felt confident handling HW. The relationship between safety training and self-efficacy warrants further investigation.

While this institution has decentralized training, current efforts are aimed at centralizing basic training through an online training platform through the institution’s learning management system. Even with centralized training, certain topics (e.g., procedure-specific standard operating procedures [SOPs] and advanced engineering controls) will require hands-on training led by the PI or the LS. Six respondents (85.7%) indicated their responsibility for providing training for specific hazards in their work area. Only one respondent disagreed with this responsibility.

Lab practices

Faculty were asked to consider their laboratory practices, facilities, and equipment (Table 2). When queried about responsibility for inspecting laboratory equipment in their work area for safety, most faculty responded positively, accepting this responsibility. Half of respondents reported maintaining a record of routine equipment maintenance, while only a third reported recording equipment repair. Of concern, half of the survey respondents reporting using defective equipment in their work area.

| Faculty perceptions regarding facilities and equipment. | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

According to both the American Chemical Society and the National Science Teaching Association, communal eyewear should be disinfected between uses to reduce transmission of diseases such as common head lice (Joint Board-Council Committee on Chemical Safety & American Chemical Society, 2009; NSTA, 2017). This is further supported in OSHA’s Laboratory Safety Guidance, stating that it is important to clean and disinfect PPE prior to storage (OSHA, 2011a). The institution’s CHP supports this action, mandating disinfection between uses for communal eyewear. However, only 16.7% of faculty reported adherence to this policy.

Most faculty accepted responsibility for performing chemical inventory maintenance for chemicals. In regard to chemical storage, 66.7% of faculty reported storing chemicals by their hazard class, which is the appropriate method, while 16.7% reported storing chemicals by frequency of use, and another 16.7% reported storing chemicals according to the project the chemicals were used for. It is possible that this level of storage was used as the primary method of segregating chemicals and that segregation by hazards was a secondary level of segregation, but that was not identifiable in this survey. Alphabetical storage is an antiquated method that no faculty reported using.

Facilities and equipment

A third of faculty surveyed were unsure if their work area had appropriate GFI outlets near water sources and 16.7% reported a need for GFI outlets near water sources in their work area. A third of faculty were unsure if their work area provided adequate equipment storage, another third of faculty responded they had adequate equipment storage, and the final third indicated insufficient equipment storage.

Half of faculty surveyed were unsure if the eye protection used in their work area was appropriate for the hazards present. In OSHA’s General Industry Standard (29 CFR 1910.133), the law states that “the employer shall ensure that each affected employee uses appropriate eye or face protection…”, referring to the standards set by the American National Standards Institute (ANSI) and the International Safety Equipment Association (OSHA, 2011a). ANSI Z87+ protects against high-velocity impact, Z87 is low-velocity blunt impact, D3 protects against chemical splashes, D4 protects against dust, and D5 protects against fine dust. All eyewear must be marked with its category. Products for smaller head sizes are marked with the letter “H.”

The majority of faculty reported one or more fire extinguishers, eyewash stations, safety showers, and chemical spill kits in their work areas. Overall, faculty were confident in knowing the presence or absence of these safety response items, with only one respondent indicating “unsure” in regard to the presence of a class ABC fire extinguisher. It is unclear if this respondent was unsure about the ABC classification of an existing fire extinguisher or unsure about the presence of a fire extinguisher. There is no explicit requirement for fire blankets in laboratories. However, NFPA 45 Standard on Fire Protection for Laboratories Using Chemicals (section 4.6.3.2) does require that procedures for extinguishing clothing fires are established (NFPA, 2019). Fire blankets can be a useful tool in such a procedure.

Safety culture

Faculty were surveyed on their engagement with the institutional safety culture through a variety of mechanisms, including communication, engagement, and perceptions of institutional commitment to safety. In faculty to institutional communication, all respondents reported having contacted safety personnel within the last year, with 83% notifying safety personnel of existing or potential safety hazards and 83% requesting safety-related professional development within the last year. However, two individuals (33%) did not receive communication back from the institution as a result of this effort. One tactic to close this loop is to streamline the communication method between faculty and the Environmental Health and Safety Office.

A large portion of respondents (83%) reported taking an active role in preparing safety procedures within their own work area, though fewer reported engagement at the department or college level (67%). However, at the campus or institution level, 83% reported involvement in this responsibility. The nature of the involvement was not explored.

Only 17% of respondents felt that the institution provided adequate resources to ensure safety. The same number of respondents also disagreed with the statement that the institution took action regarding safety issues raised by employees. Because a proactive safety culture requires a core commitment to safety from all levels, feedback must be taken seriously in order to address false perceptions appropriately and promote open communication. While the sample size prevents reporting of a correlation, it is interesting that those who indicated they know the point of contact in administration regarding safety appeared to be more likely to support the statement that administrators take action on safety issues raised by employees. This potential correlation justifies further investigation in future studies.

Another question that highlighted concerns with self-efficacy focused on faculty confidence that their laboratory practices met federal guidelines. Surprisingly, only 17% of faculty agreed that their laboratory met guidelines, with no respondents suggesting they strongly agreed. Half of the respondents were unsure if they met guidelines while 33% strongly disagreed, suggesting they are aware that they are not meeting federal safety guidelines. It is unclear if this understanding was achieved through this survey or prior to this survey. Question placement could have biased this question. The final question of the survey suggested hope: Eighty-three percent of respondents suggested they would support a nonpunitive review of their work area for compliance with federal and institutional guidelines, with most suggesting they strongly agreed with this. With this review executed through the Environmental Health and Safety Office, strong communication between faculty and safety personnel can help develop a safety community rather than a confrontational or punitive atmosphere.

Limitations

Nonresponse error is a significant limitation of this study. The n of eight did not allow us to confidently determine if correlation results were statistically significant. We elected not to report significance results so as not to mislead the reader. However, it should be noted that low survey response rates may be a symptom of a larger issue of organizations placing too little emphasis on safety as a discipline. With a limited respondent pool, it was not possible to look for correlations between safety attitudes and disciplinary expertise, industry connections, or years of experience.

Geographic limitation of this survey is a limitation. Results may be different based on geographical scope. Safety may be viewed differently in industrial areas of the United States, thereby generating different levels of survey response and attitudes toward safety practice.

The design of this study did not analyze reliability and the results were not confirmed with known group validity because it is unlikely such group validity exists for the sample population. This limitation leads to low external validity. This study provides insight into safety culture at the test university, but does not necessarily describe safety culture in teaching and research laboratories at other institutions, even of similar size and composition. Future work will include multiple universities in order to improve external validity.

Measurement errors may have occurred where survey statistics differ from the true value due to the data collection methods. Poor question wording and a poor understanding of survey questions are confounding factors that are mechanisms for this error. Bias is a concern in voluntary self-response, which may over-represent strong opinions. It is unclear how this limitation impacted the results.

Broader implications

Challenges abound, some that mirror “No news is good news” or “Do we have to report the minor accident?” However, this leads to “Tomb Stone Safety” where procedures are not written and reviewed until after a major accident happens (Del Balzo, 2017). Safety programs, inspections, and training cost money and time. However, effective policies and training prepare faculty, students, and/or employees to act in crisis situations or, preferably, before an accident occurs. A modern take on safety culture applies three tenets: safety is an ethical responsibility, people are the solution instead of the problem, and safety is the presence of positive capacities rather than the absence of negative events (Dekker, 2014).

Safety is a critical aspect of any organizational mission. The loss of life, limb, or function is a huge price to pay for not (1) having adequate safety measures in place where (2) students and faculty know how to access them in order to (3) develop work behaviors that include ingrained awareness and safety practices. Students and faculty alike conduct experiments and labs that model procedures they may encounter out of the university setting. Safety is a discipline. It goes beyond common sense and should be inculcated at the earliest stage of professional development. Safety as a discipline requires continuous reinforcement for a safety culture to flourish. Safety awareness and safety attitudes are transferable skills. Unfortunately, the world is not an inherently safe place. Safety is not a passive activity nor is it the absence of accidents. When accidents or injuries occur, after-action reporting is necessary not only to identify what happened, but to prevent similar occurrences from happening again. The aviation and medical fields have taken the lead on root-cause analysis and after-action reporting, but the importance of well-organized safety programs crosses over into other industries as well (Del Balzo, 2017). Safety is a concerted effort by organizational leadership and team members to minimize mistakes and injuries (Lundell & Marcham, 2018).

Conclusions

A strong safety culture has engaged employees. One of the key limitations of this study —the small sample size—highlights the concern over lack of engagement. We hypothesized that less than 25% of the potential participant pool would respond to the survey; 15% did. The low participation rate in this study may be due to attitudes toward safety and reluctance in reporting safety perceptions and behaviors.

The second hypothesis was that training has a positive impact on faculty’s belief in their ability to succeed regarding use of safety policies and procedures. While correlations in this study have low significance due to the low participation rate, we can see that there appears to be a relationship between training and key aspects of training such as the location of the CHP, SDS, and safety reporting system. Training appears to be correlated to knowledge of hazardous waste disposal procedures. However, quite interestingly, there was not an apparent correlation between hazardous waste training and confidence in making hazardous waste determinations, suggesting low self-efficacy in this area. The correlation between safety training and self-efficacy warrants further investigation.

This study also showed a concerning trend of laboratory activities that not only violate institutional guidelines and contradict training, but also pose safety risks to faculty, staff, and students. Faculty reported using defective equipment and a low rate of disinfection of communal eyewear between users. Lab supervisors have a responsibility to set the example and to ensure the safety of those working in their laboratory. Therefore, all lab supervisors should ensure adequate storage for equipment, be aware of needed and implemented engineering controls such as GFI outlets, establish appropriate administrative controls (e.g., SOPs), and ensure proper eye protection is available for workers. Our survey suggests this is an area of growth.

The results of this survey reveal that there are gaps in actual engagement of some levels of the safety culture (e.g., disconnected communication) as well as perceived gaps in engagement (e.g., perception of inadequate safety resources). There is promise, though, that faculty report strong engagement in preparing safety policies and procedures at all levels. While this survey could not adequately explore the hypothesis that organization engagement with safety culture at multiple levels positively impacts faculty self-efficacy regarding safety, this survey does provide foundational evidence for how to explore this more deeply in a future study. Faculty are open to nonpunitive review, which may have a positive impact on faculty self-efficacy. It would be interesting to more deeply explore how the connection between a disciplinary approach versus a collaborative approach could influence self-efficacy.

The literature review suggested that there is weak safety culture within academic laboratories. The research indicates this remains problematic to address within higher education. Future researchers should explore management and employee attitudes toward safety to determine if these attitudes are a barrier to effectively reporting safety compliance data. Future researchers could also compare and contrast safety attitudes and behaviors based on moderating variables such as age, gender, experience, title, field of expertise, connection to industry, and other potential moderating variables.