feature

Rider Root Beer

The Science Teacher—July/August 2022 (Volume 89, Issue 6)

By Ehren Whigham, Jerrid Kruse, and Kate Galligan

Safety Considerations

Because compressed gasses pose a safety concern, the teacher was responsible for procedures involving the CO2 tank. Students must be aware of potential safety concerns and we were sure to monitor students carefully as they worked. Specifically students should:

- wear indirectly vented chemical splash goggles, vinyl or nitrile gloves/hot gloves, and non-latex aprons,

- use hot gloves to handle lids and while stirring,

- do not look directly into hot mixtures, and

- pour liquids into milk jugs only over spill containers.

- Note: drinking root beer made in the lab carries a risk of cross contamination and therefore should not be done.

We begin each school year with a questionnaire. One question asks students about their parents’ jobs and if they might be interested in coming in to speak to the class. Because we teach in a large, urban school district in the Midwest, typically a few students have parents who work in the sciences. One year, we were fortunate to have the child of the owner and head brewer of a local microbrewery. We didn’t know then, but that coincidence set the stage for a major collaboration to bring the real world of chemistry and biology into our classrooms.

Craft beer production in the United States is on the rise, as is the production of craft soda. Similar to Cubbage (2019), we wondered if the brewing process might help us couple the content of our courses with the NGSS science and engineering practices. What if our students collaborated to design a recipe for a craft root beer? If we could generate a quality product, the microbrewery could help with production and distribution. Three years later, Rider Root Beer was a reality. Through this project we were able to help students apply their understanding of aerobic and anaerobic cycling of matter and flow energy (HS-LS2-3) as well as develop their understanding of the nature of engineering (HS-ETS1-2).

Recipe design and brewing

To begin this engineering task, students in the authors’ biology and chemistry courses (primarily juniors and seniors) were instructed to find a partner and design a one-gallon root beer recipe. Given that we had never made root beer or worked at a brewery, no formal constraints were put in place. To begin the first iteration of the engineering cycle, some students went online to find examples of recipes for home-brewed root beer, while other students went to the grocery store and found a variety of craft root beers to look at ingredient lists.

We asked students what we might need to consider if the goal were to scale up this recipe for production at a brewery (ETS1-2). Students noted that the cost of ingredients would also scale, measurements would need to be precise, and the ingredients would need to be available in bulk. We then drew students’ attention to the crosscutting concept of scale, proportion, and quantity by asking, “How does creating our recipes at a small scale help us plan for and refine the large-scale batches we’ll need to make?” Students easily recognized the need to identify precise measurements to accurately determine proportions in the large-scale recipe.

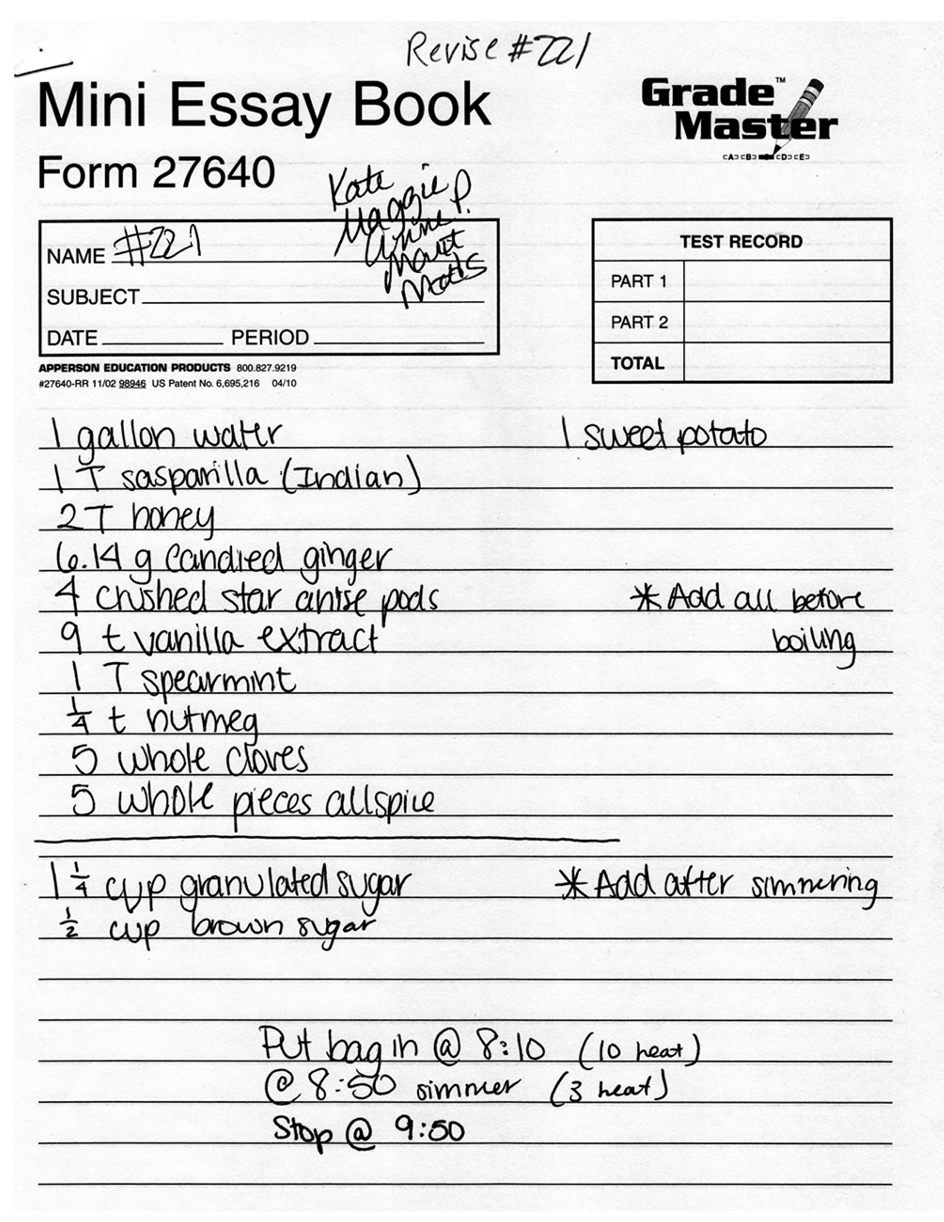

From this discussion, we were able to help students understand the limitations of some sweeteners (e.g., honey) and the prohibitive cost of large-scale batches. Armed with this information, students continued the engineering cycle by creating their own recipes (Figure 1). With financial support from our principal and the local microbrewery, we purchased common root beer ingredients from a local homebrew supply store including several different tree barks, star anise, some different sweeteners, and some bittering agents.

Sample root beer recipe.

To draw students’ attention to the nature of engineering we asked, “Why does it make sense for engineers to start with a small batch or model before scaling up?” Students quickly recognized the benefit of avoiding waste and conserving materials, as well as providing a proof of concept. To help students think about their process we asked, “If we want to make this again, and eventually have other people make it, what do we need to think about on the first attempt?” Students suggested using lab notebooks, as we had done for other labs that year. They listed several numbers each group should record, including times for adding ingredients, volume of ingredients, and the temperature of the liquid at each step.

As students worked on their recipes, we looked for additional ways to draw their attention to the nature of engineering. For example, one student suggested adding gold flakes to a batch. We then asked, “How might affordability of the root beer create a constraint in this situation?” (ETS1-1) Students easily recognized that they needed to create a product that is both desirable and affordable. We extended this conversation by asking, “What other sorts of constraints might engineers face?” Students pointed out constraints concerning size of the batch and availability of starting materials. These initial planning and recipe development tasks took students approximately two hours.

Later, we spent a full 90-minute block brewing. We brought in the largest pots we owned, and borrowed a few from the family and consumer sciences teacher. Using hot plates and portable electric stove tops, students heated water and added ingredients according to the recipes they had created. Each group was instructed to record the details of their process in a lab notebook for future reference. This was an exciting day! The lab was full of interesting smells, and each pot contained a unique, colored liquid. When the brewing was complete, we let each mixture cool and then poured each gallon of fresh root beer into a milk jug and cooled them all to 4°C.

Carbonating the root beer

Because the students working on this project were primarily juniors and seniors, and all had taken introductory biology, we drew on their understanding of Ecosystems: Interactions, Energy, and Dynamics (HS-LS2). One of the performance expectations (HS-LS2-3) asks students to construct and revise an explanation based on evidence for the cycling of matter and flow of energy in aerobic and anaerobic conditions. Therefore, we wanted to make explicit and help students refine their understanding of the relationship between cellular respiration and fermentation.

We started this discussion by asking, “For living things, what is the benefit of aerobic respiration compared to fermentation?” After students recalled that much more ATP gets produced in aerobic conditions (DCI LS2.B), we asked, “Why would living things undergo fermentation?” This question led to discussion about places without oxygen, like the early Earth, and places with not enough oxygen, like muscles during a workout.

We concluded that while aerobic cellular respiration yields much more ATP per molecule of glucose, fermentation enables life to persist even when oxygen is not present. Given that when yeast ferment sugars, they generate ATP, CO2, and ethanol, we asked students, “Where are the by-products of fermentation useful in your world?” Students recalled that ethanol gets blended into gasoline and carbon dioxide causes bread dough to rise.

We then asked students to consider what would happen to the sugar in our soda if no yeast was added. Most students quickly acknowledged that without yeast, no fermentation would occur, and that the sugar would remain in the solution. We followed up by asking, “If the sugar remains in the solution, what does that mean for our soda and the people who drink it?” Our discussion centered around the idea that humans use cellular respiration to harvest energy, while yeast use fermentation, but the energy that drives both processes is stored in the same molecule: sugar. This content can be addressed in the lab using a classic fermentation experiment articulated by Bartlett (2002) and extended by Bullerwell and Hagar (2003).

To get around fermentation, and the problematic alcohol it produces, we force-carbonated the root beer using a borrowed homebrew setup. Because there is no yeast, there is no fermentation, and no alcohol. Instead, a tank of compressed CO2 was connected to reconditioned five-gallon soda kegs.

At this point, we helped students consider the equilibrium between dissolved gas and non-dissolved gas by asking, “Why do you think an open soda goes flat but an unopened soda doesn’t?” Students speculated that the gas “comes out” of the can and makes room for more gas to come out of the liquid. We capitalized on this idea by asking, “So if gas can leave the soda when there is space, what might happen if we could somehow pump gas into a bottle of flat soda?” When students speculated that gas might go into the liquid, we helped them formalize their thinking and made explicit the crosscutting concept of cause and effect by drawing the equilibrium on the board: CO2(aq) ← → CO2(g). We explained that decreasing pressure on the gaseous side of the equilibrium causes the equilibrium to shift so that CO2 comes out of the liquid, but putting pressure on the gaseous side shifts the equilibrium so that CO2 enters the liquid to create carbonation.

Evaluating batches

The day following carbonation, we tasted in silence and wrote notes about each recipe before comparing our experiences. The first round of recipes were almost all unpalatable. We could see the disappointment on the faces of our students so we asked, “What did you learn from today’s tasting?” Students responded, “We are not good at making root beer” or “From now on, I’ll just buy the root beer I like.” We then asked, “What could you change when we try again?” The students observed in almost every case too much sugar was added. They noted the flavors they could taste that they liked and many were excited that they would get to try again. This experience completed the first iteration of the engineering cycle and was a perfect opportunity to discuss the value of failures in science and engineering so we asked, “Why do you think iterations are an important part of how engineers work?” With their fresh experience of failure, students easily noted that sometimes ideas don’t work and learning from mistakes is valuable.

Preparing for the next iteration

We noticed that students had not paid much attention to how they implemented recipes (e.g., measuring). So, we held up a heaping tablespoon and a level tablespoon and asked, “Why would these measurements not result in the same outcome?” Once students recognized this problem, we expanded their thinking by asking, “What other factors might we need to watch more carefully?” Students noted that star anise was a particular challenge because it was not a powder. One student suggested recording the mass of ingredients instead of the volume, which went over well with the rest of the class—notably, the brewery uses mass to measure the hops they add to their beer. Other students admitted that they did not record specifically when they added each ingredient or how long they boiled their brew. Although obtaining, evaluating, and communicating information is a science and engineering practice addressed in many courses, that day we saw many students truly realize the value of a laboratory notebook.

Continuing the project

New biology and chemistry students took over in the second year of development. Many of these students were already aware of the project as the smell of root beer in the science wing had earned us some notoriety. These students were given the recipes and feedback from the previous year and were assigned with improving aspects including flavor and color, in addition to refining production processes like boil times and when to add each ingredient. This went better, as the products started to taste and smell more like root beer. Logistically, the bulk of testing and development occurred in the second half of the spring semester. By that point, students had experience with DCIs covered throughout the year that they could now apply to the root beer project. In addition, after AP exams some of our students were left with more time. Through iteration and taste-testing, the best recipes moved forward, while the less-desirable ones were discarded. At the end of year two we had products that tasted almost like root beer.

In year three, a few students in the gifted and talented program took on leadership roles in the project. Rider Root Beer was gaining steam. The business/entrepreneurship teacher agreed to have students work on business models. Students in these classes met periodically with employees from the brewery for feedback on their ideas. Upon learning that 32oz growlers were likely the initial production vessel, they recruited the art department to develop bottle designs. Later, students organized meetings with a local marketing company used by the brewery, and the marketing classes used Rider Root Beer as an in-class project. All the while, student leaders pushed for progress toward a final recipe. Some students even came in on weekends to brew new recipes to ensure we’d be ready to launch by spring of year three.

To help students see the interdisciplinary nature of engineering we asked, “Why do you think understanding science alone would not be enough for a project like Rider Root Beer?” With some excited discussion, students concluded the success of Rider Root Beer was grounded in the confluence of science content, engineering process, business planning, eye-catching marketing, and skilled artistry. When pushed to consider how this multidisciplinary approach applies to scientists, students said things like, “Writing grants is similar to selling a product,” “Scientists have to manage the finances of a working laboratory,” “Some scientists are in charge of supervising people [technicians and graduate students],” and “Sometimes scientists give presentations and need to communicate complex ideas to people who might not understand.” Never in our experience as science teachers had students come to realize how multidisciplinary science has become.

The launch

Finally, after three years of patient progress, Rider Root Beer was ready to launch. The root beer was produced and bottled by the microbrewery. The first batch of 800 bottles was distributed from the high school and sold out in 36 hours. Since then, more batches have been produced, with a portion of the profits donated back to the high school. Though the initial project envisioned a collection of craft sodas, the collaboration ended when one of the authors moved to a different school. ■

Notes about force carbonation

- The reconditioned soda kegs were purchased from a local homebrew supply store and had been tested to ensure integrity under pressure.

- YouTube video instructions on force carbonating soda: https://youtu.be/knQCijId8f8

- YouTube video instructions for how to clean a keg: https://youtu.be/CbpFdIU-i_k

- We used a common sanitizer obtained from a homebrew supply store to sanitize all instruments used in the production process.

- Ingredients used were all food safe and boiled prior to carbonation.

Ehren Whigham (ehrenwhigham@creighton.edu) is the Laboratory Supervisor in the Department of Biology at Creighton University in Omaha, NE and Jerrid Kruse is the Baker Professor of Education at Drake University, Des Moines, IA. Kate Galligan is the Chemistry/AP Chemistry teacher at Theodore Roosevelt High School, Des Moines, IA.

Biology Chemistry Interdisciplinary Labs Science and Engineering Practices